Click on one of the following categories:

General Questions

Are Performance Trends' programs

compatible with Windows Vista and Windows 7, 8 and 10?

What if I don't know some spec the program is asking me?

Why is the program predicting more performance than I'm

seeing on the dyno (or at the track)?

How do I use a simulation program?

What is the advantage of using a simulation program?

How can I Email you a data file to show you a problem I'm

having with a program?

Can I use your Windows programs on my Apple Mac (Macintosh)

?

What is error 429?

My program runs very slow and is locking up.

The scroll bar in the table at the lower left is flickering.

How do I share data files on a

hub (network)?

My security (virus checking) software says my

program is infected. What should I do?

My software runs, but it takes

1-2 minutes for the graphs to come up. What is wrong?

Performance Trends' software has many

messages. How can I get through these messages faster?

When I press the Function

keys in the Performance Trends software, nothing happens. Why?

Engine Software Questions

Are these (Engine Analyzer) Programs accurate?

The Seat (advertised) Timing for my cam

does not match my cam's actual specs. How can I adjust this?

The program's Seat (advertised) Timing

and Duration for my cam

does not match my cam's actual specs. Can the program still be accurate?

The Roots Supercharger I Installed

Shows No Boost. Why?

I just made a small

change to the turbo specs and it made a HUGE difference in power. Why?

In the Engine Analyzer programs, what is the advantages and

disadvantages of going higher than 75% on the Total Exh/Int %?

How do I simulate a restrictor on an EFI engine with a

plenum and individual runner throttle plates?

Why does the spark advance value only increase by maybe 10

degs from idle to 3000 (even on stock setups) when actual distributors have

15-24 degs of advance?

Which cylinder heads have a "Compact Wedge"

combustion chamber?

How much harder is Engine Analyzer Pro compared to Engine

Analyzer?

Why can't I get the Engine Analyzer to match the factory

torque and HP ratings for 1960s muscle cars?

How do I enter or calculate the "Corrected Compression

Ratio" for my supercharged engine?

Is the Engine Analyzer doing ECA (Engine Cycle Analysis)?

Why does the Engine Analyzer Pro show that some Thermal

Barrier Coatings reduce performance?

Does the Engine Analyzer or Engine Analyzer Pro consider

Port Size (volume) when estimating Performance?

My Turbo catalog only lists lb/min for airflow not cfm as

Engine Analyzer uses. Is there a formula to convert lb/min to cfm??

Can the Engine Analyzer and Engine Analyzer Pro be used for

small engines, like a 5 HP Briggs?

The Spark Curve reported by the Standard Engine Analyzer

starts high, then drops down, then increases again. Is this possible?

Do the Engine Analyzer calculations consider Turbo A/R in their

calculations? Do I alter the Turbo CFM rating to simulate different exhaust

turbine sizes?

I have cam timing specs .020" lift intake and .025"

lift exhaust. Currently I am using the valve lift graphs to determine

where the .050" lift point is from where I see the .020" and

.025" lifts. Is there an easier way to figure this out?

How do I enter the weight of my crankshaft,

pistons or rods so I can see the effect on HP?

What is the formula for determining

Intake Valve Closing angle in the Compression Ratio Calculator?

Why does the Engine Analyzer and the

Engine Analyzer Pro give different results for Detonation (spark knock)?

Why is there a dip in the torque and HP curve at 3500 RPM?

How

do I build an engine to run a certain quarter mile ET and MPH?

How can I speed up the

Calculations in Engine Analyzer Pro?

I've run the same exact

std Engine Analyzer conditions and the Engine Analyzer Pro does not give the exact same

results. Why?

What should I adjust to get the

Engine Analyzer results (std, Plus or Pro) to match my real dyno results?

I'm a little confused about measuring Port Length. Is it measured

along the short side of the port?

How can I export the cam

profiles and cylinder flows and pressures from Engine Analyzer Pro to Excel?

How can I create a cam file to be read by Engine Analyzer Pro or other

Performance Trends software?

I don't know much about my

engine. How can I build an engine file for it?

When

calculating Average Port Diameter, what do I use for the Port Length?

How do I use a

.jpg file of a turbo compressor map for entering a detailed

map into Engine Analyzer Pro Enterprise Edition?

Why does the program show air flow of 600 CFM,

but the carb CFM rating is 850 CFM?

How do I measure the Intake

Runner Length and Diameter for my Individual Runner Weber carbs?

What is the difference between

Designed Valve Lash and Actual Valve Lash?

How do I figure out how to enter

the information the Engine Analyzer Pro needs, for example for Bearing Size

Coefficient?

Port Flow

Analyzer Software Questions

If I build an

EZ Flow flow bench just using a shop vacuum as the flow source, how will that affect my data?

My EZ Flow

System shows I have CFM flow when the motors are turned Off. Why?

My Black Box II will not communicate to my

computer. What should I do?

Does my flow bench

require corrections for weather changes?

How do I copy my

program from an old computer to a new one?

How do I share data files on a

hub (network with shared folder on server and clients)?

I lost the power supply for my Black Box II. Can I get one at Radio

Shack?

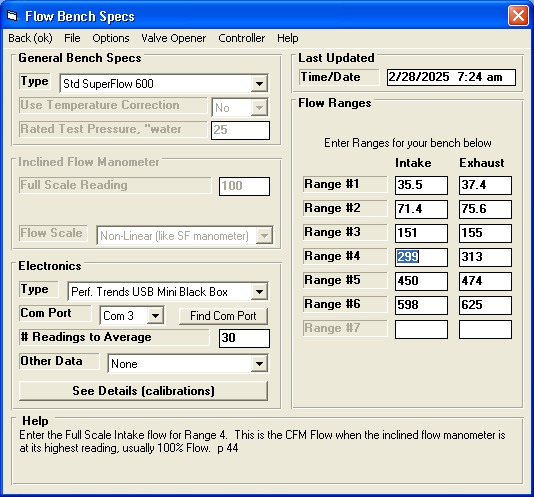

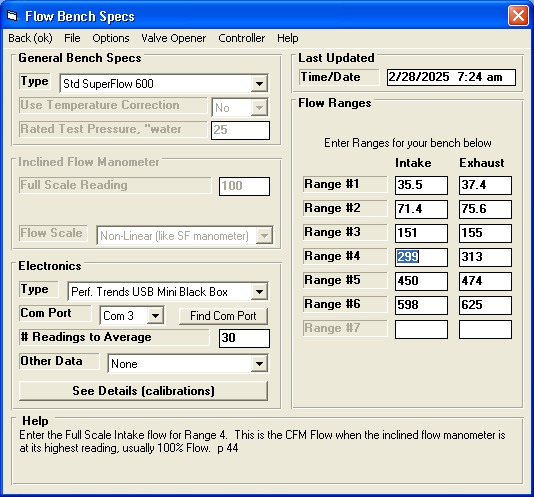

What is meant by Master Bench Specs?

(Note: This answer is provided using the example of Master Dyno DataMite

Specs)

My Black Box II

readings do not exactly match my manometer readings at some points. What

can I do?

My Flow Bench readings seem

erratic or inaccurate, even based on my manometer readings. How can I

troubleshoot this?

Besides CFM Flow, what can I measure on a flow bench?

Why won't my automatic valve opener

find the tip of my valve?

What can

I check on my Electronic Velocity Probe to see if it has a fault?

Are the Electronic Velocity Probes as accurate as the traditional pitot

tubes?

I'm having trouble understanding how to get my Valve Opener to work with

my SF1020 to automatically do a flow test. Can you help?

We flow components

like air cleaners at different test pressures. Can the Port Flow Analyzer

do this?

How do

I adjust my Port Flow Analyzer to match the CFM from a calibration orifice

plate?

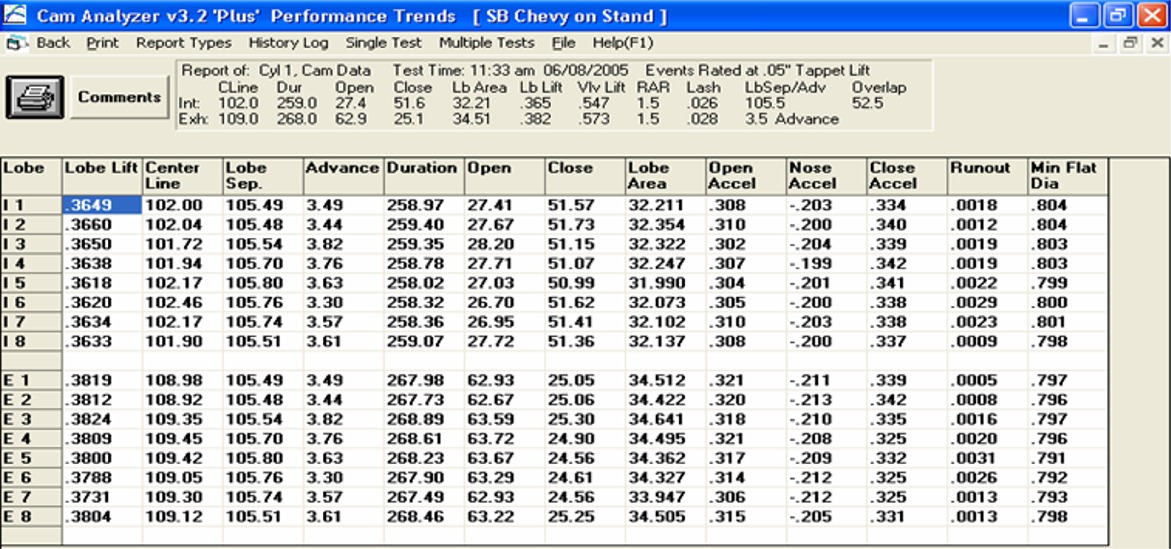

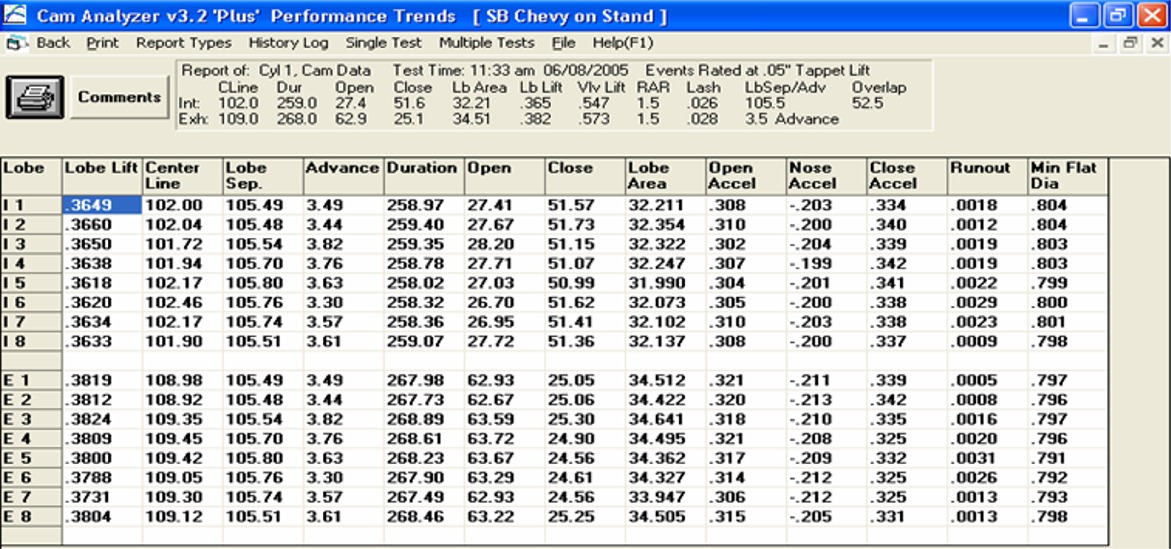

Cam Analyzer / Cam Test Stand Questions

How does the software know

my cam timing when I measure the cam on the Cam Test Stand?

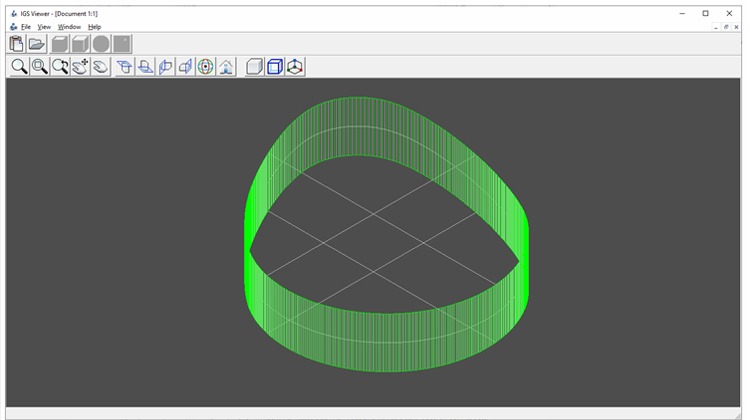

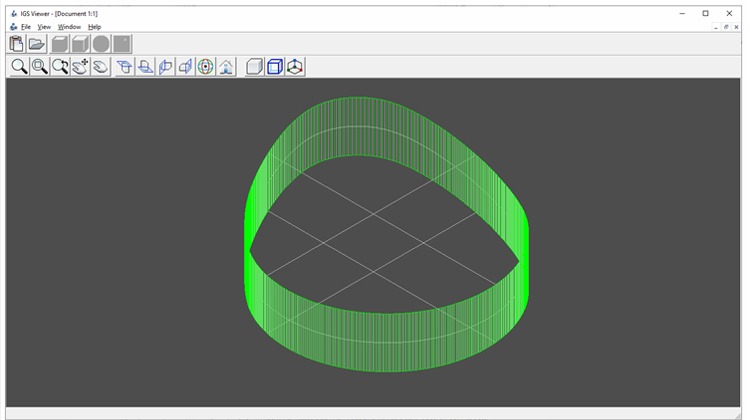

How do I convert a cam file

(CPP, S96, Cam Dr, etc) to a manufacturing

type file (.p, .igs, .iges, X/Y, etc) for a CNC cam grinder.

I have a cam profile in Excel and I want to use it in my Cam Grinder with

a large grinding wheel. Can Cam Analyzer make that conversion?

How do I create a

manufacturing file to exactly copy of a cam lobe I just measured?

Can I figure out how much to reduce the base circle for regrinding an

existing cam for larger lobes and lobe separation?

Can I create an XY or polar angle/length file for roughing out a cam on my

CNC from .050" duration and max lift data only?

I have an OHC engine, with 2 cams,

an Intake and an Exhaust. How do

I set this up?

I measured my diesel cam with a .750" and .850" roller and show

very little difference. Is this correct?

I measured the cam with the pointer

directly on the lobe and the results don't look anything like the Cam Catalog's

Specs. Why?

My Results do not repeat when I measure the

same lobe again. What could be happening?

I'm using the Virtual Follower feature,

but my results do not look like what the cam should be?

What is the advantage of using

the Universal Flat Tappet (or TDC Checking Bridge) to Find TDC?

Will the software let you

extrapolate from a .750 inch diameter roller lifter to a .800 inch diameter

roller?

Do I need a different follower

for every type of cam I measure?

Do I need to zero out the linear

encoder (lift measuring device) before I measure a lobe?

I've got a cam with multiple lobes for

each cylinder. How can I export a Cam Dr file to the Engine Analyzer Pro?

If I want to check a cam in the engine (or an OHC

cam in the head), what do I do different?

Filtering seems to have a large effect on the

acceleration readings. What is the correct Filtering setting to use?

What is meant by Master Tester Specs?

(Note: This answer is provided using the example of Master Dyno DataMite

Specs)

How can I create a cam file to be read by Engine Analyzer Pro or other

Performance Trends software?

I'm a cam grinder, and I want to see all

lobes spread out like when viewed from the end of the cam. Is that

possible?

My Black Box II will not communicate to my

computer. What should I do?

Can the Quick Cam

Checker create a cam file to be read by Engine Analyzer Pro or other Performance

Trends software?

When I graph the Jerk for a profile,

it just seems to be a bunch of jumpy lines. Why?

Can I find TDC with the

linear encoder on the top of the piston?

How can I tell if a cam is

hydraulic or solid, and if solid, what lash it is designed for?

Why does the Radius of Curvature jump around so much?

I'm

measuring in millimeters. Why do my lobes look so "rough", like

stair steps?

How do I check if the rotary

and linear sensors are good?

Can I import a lobe from 1 file

into another file? or Can I combine 2 files together?

I'm getting a "bump" in my profile when

trying to do virtual follower on a cam file I've imported from a different

software. Can I fix it?

I'm measuring my OHC

rocker arm cam with Intake and Exhaust lobes on the stand (not in the

engine). How do I set this up in the software?

Engine Log Book Questions

What measurement

gauges will load info directly into the Engine Log Book?

My Mitutoyo bore gauge will not communicate

with the Engine Build Log Book. Why?

Valve Spring Tester Questions

After testing my

valve springs, can the software tell me the required install height to produce a

certain seated force?

Drag Racing Software Questions

How can your Drag Racing Analyzer accurately

predict Dial Ins and Throttle Stops if it doesn't let me enter several past ETs

and weather conditions about my car.

I want to optimize my car to

produce the quickest time to accelerate between 2 different MPHs. How can

I do this?

How

do I build an engine to run a certain quarter mile ET and MPH?

Do I always have to make 2 runs to "calibrate" my

Drag Racing Analyzer for predicting Throttle Stops?

How do I import Drag Race

DataMite data into my Drag Race Pro 'Team Engineer' simulation program?

How do I measure the car's

Center of Gravity Height, or CG Height?

Why can't I just type in my

converter's stall RPM and have the program always use it for "stall

RPM"?

How do I adjust my ladder

bars in 4 Link Calculator to prevent wheelstands?

My 4

Link Calculator does not draw my ladder bars correctly. Does that

matter?

Suspension Software Questions

I don't know which suspension

program to get. Can you help? How about Dirt vs Asphalt?

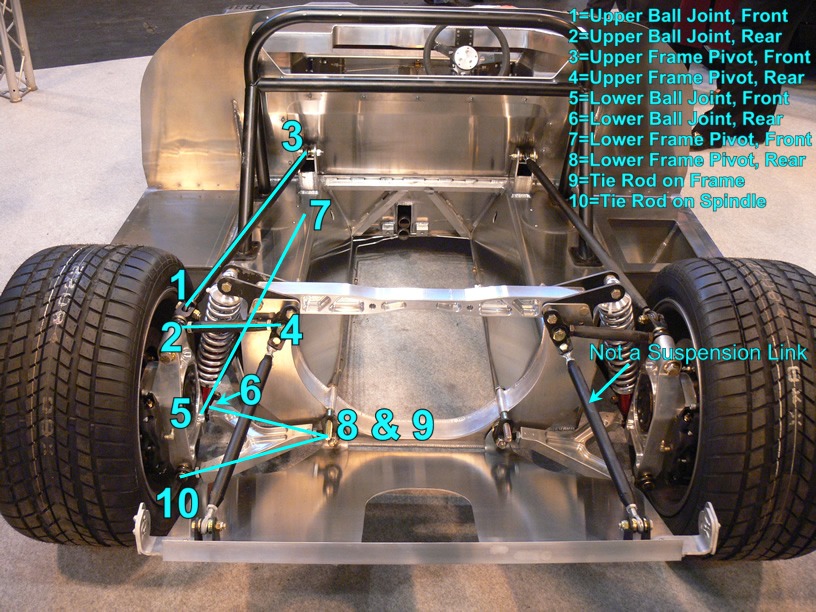

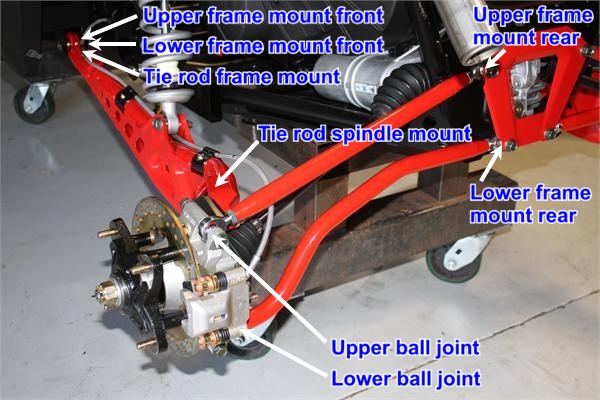

In the Roll Center Calculator and Circle Track

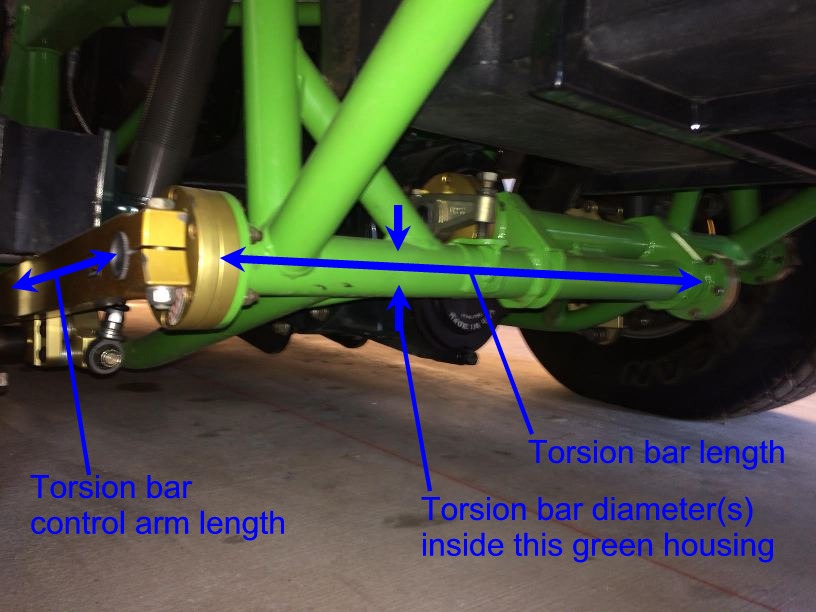

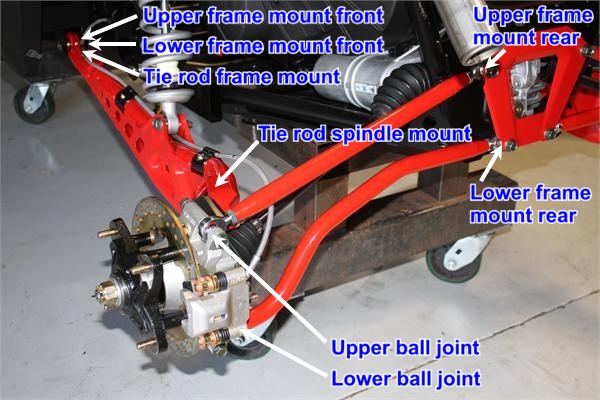

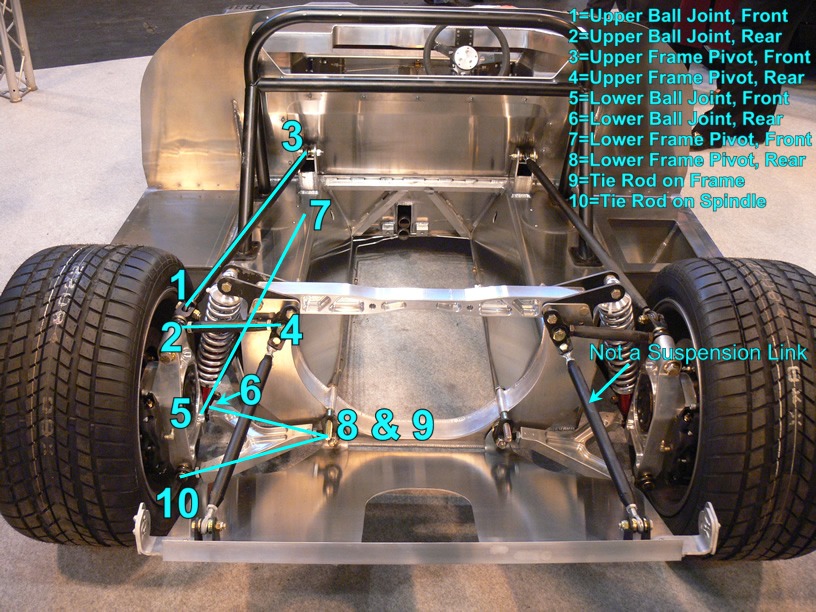

Analyzer, how do I measure where the Frame Mounts for the A Arms are located?

Do you have software which deals with Rear

Panhard Bar settings?

Why doesn't Circle Track Analyzer showing a change in lap

times when I change suspension settings?

When the Roll Center gets close to ground level, it moves

left or right dramatically for small changes in dive and/or roll. Is this

correct?

Can the Circle Track Analyzer be used for dirt track racing?

Can I use my Data

Logger data (from your DataMite II or my own data logger) in your Suspension

Analyzer to see what my suspension is doing on the track?

In Suspension Analyzer, why

is the Ackerman Error not the same for both tires?

In Suspension Analyzer, what

is meant by "binding error"?

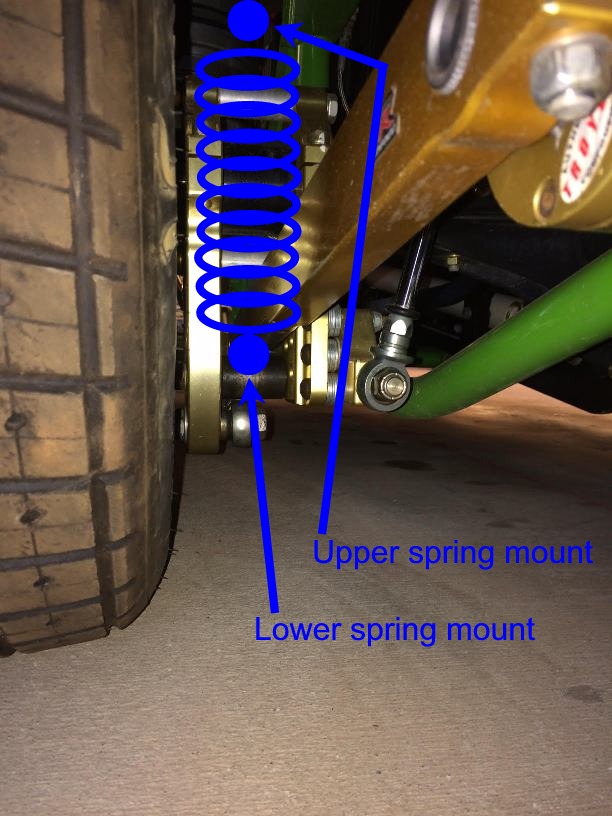

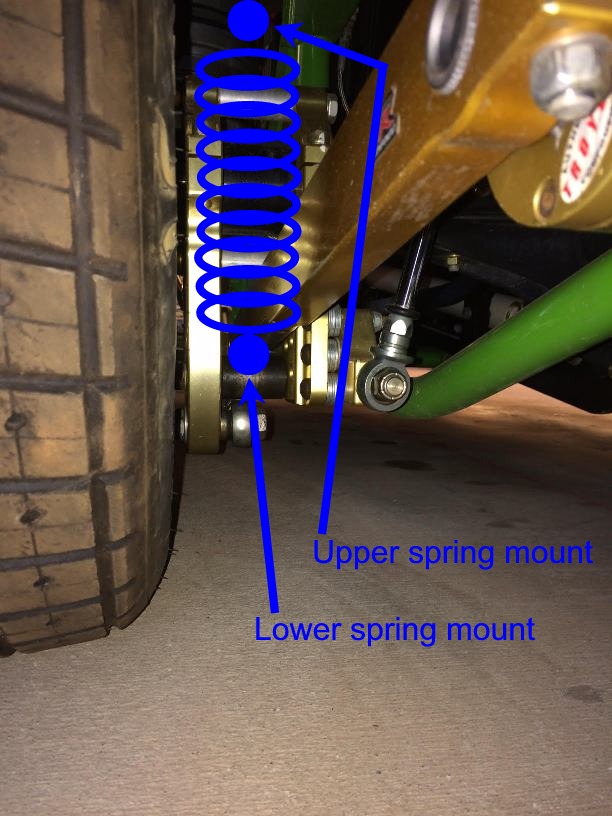

The Spring Motion

Ratios calculated in Suspension Analyzer do not match my hand

calculations. Why?

My Suspension is not exactly one of the choices available in the

Suspension Analyzer. How can I simulate it?

How do I measure the car's

Center of Gravity Height, or CG Height?

The programs let me put in Dive and Roll to

watch what happens when the suspension moves. How much should I tell the

program?

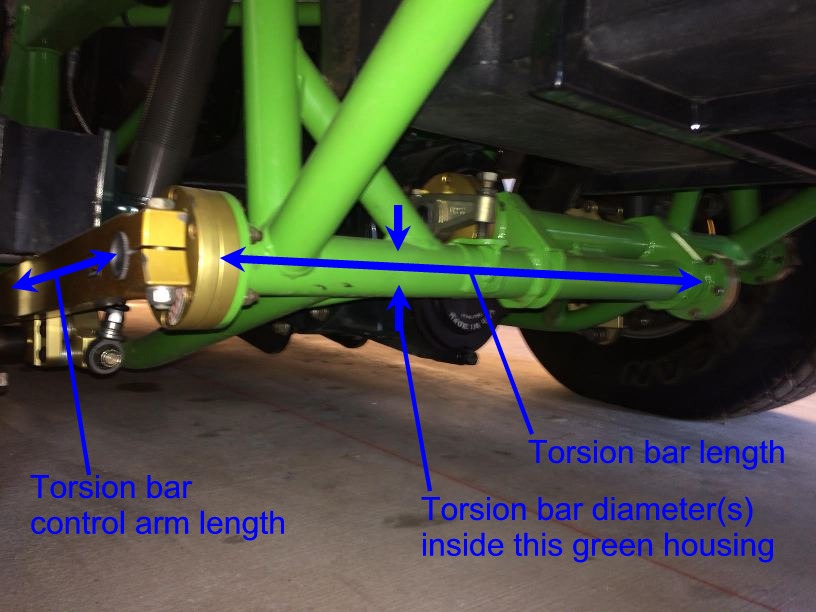

Can you explain the

different labels for the 5 Link rear suspension points?

What should I use for the vehicle's centerline when I measure my

suspension?

How can I graph data from my

front suspension with that from a rear suspension?

Dyno DataMite Data Logger Questions

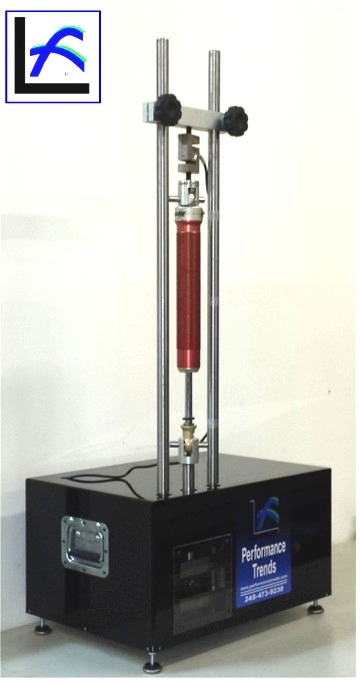

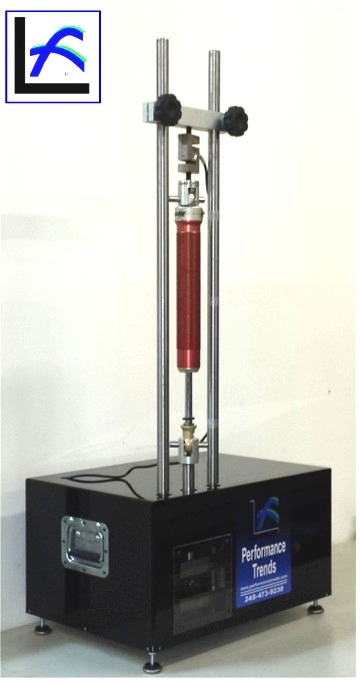

I'm building an inertia dyno

myself. How do I figure out how big to make the flywheel, or the roller

for a chassis dyno?

I'm having trouble getting my USB DataMite to "talk" to my

computer. How can you help me?

When I start my engine (or

go to full power), I lose communications with my data logger. How can I

troubleshoot this?

Do you have classes to teach user's all of the DataMite software's

features?

How do I hang weights on my

dyno for calibrating the load cell for torque?

My torque reading is not reading

zero with the engine not running. How can I rezero the torque (or most any

analog channel) reading?

When

hanging weights to calibrate torque, the numbers can change by how I hang the

weights. How can I be more accurate?

How do I know what A/F

to shoot for when I change fuels?

Can the DataMite software

use vehicle coastdown data on a chassis dyno to estimate driveline losses, and

therefore produce flywheel torque and HP numbers?

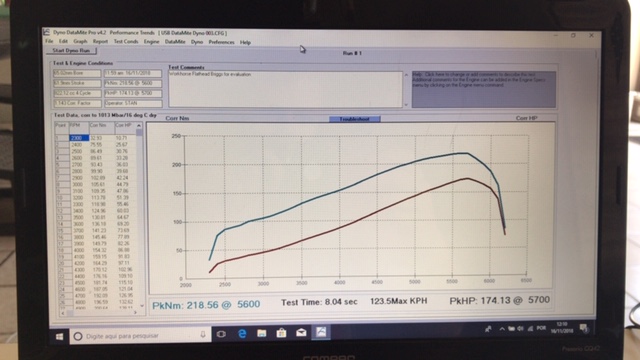

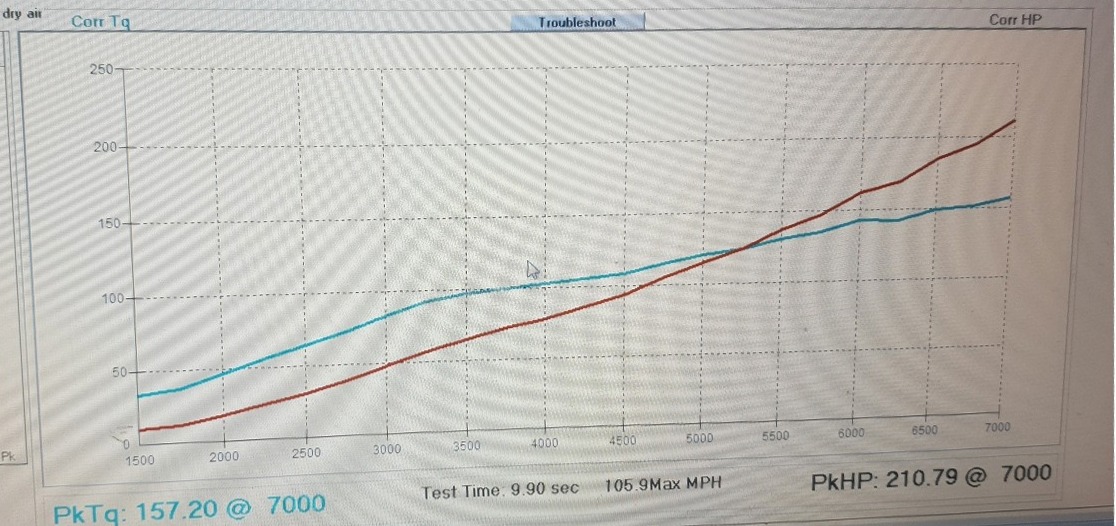

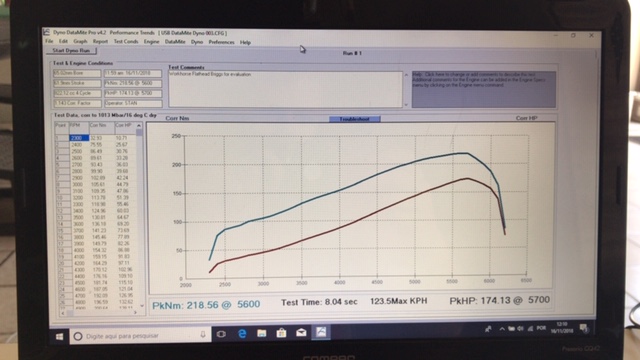

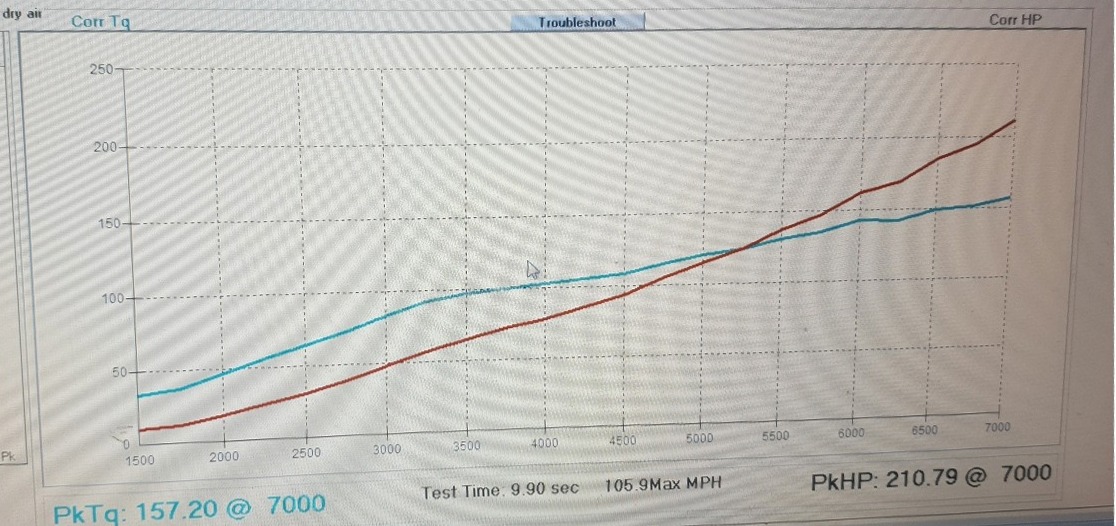

When trying to achieve accurate inertia

dyno results, what are the main things to consider?

By accurate, I mean as close to true horsepower as possible.

What are the main considerations when trying

to achieve repeatable inertia dyno results?

By repeatable, I mean test-to-test and day-to-day consistency.

What are the main considerations when trying

to achieve accurate and repeatable water brake dyno results?

When I dyno an engine using an Inertia Dyno

and your DataMite, the HP seems to peak too early, say 9,500 RPM, when I

actually rev the engine to 10,500 RPM on the track. Why?

The Torque Peak and HP peak reported on the

Main Screen is slightly different than what I see on the graph which is slightly

different than what I see on the report. Why?

Can I use just engine RPM or Dyno Wheel RPM

(not both) to calculate torque and HP?

How do I measure Engine RPM on a chassis dyno?

Can I use just your software for

an existing dyno?

How does your software and electronics control the dyno?

How will I run a test with a water brake dyno?

Is my load cell working in

tension or compression?

Can most of the USB DataMite III or 4 features be added later if I

don't buy them now?

How can I troubleshoot bad or "corrupt" data I'm getting from

the Black Box II Dyno System?

Can you do a "coastdown" test on our chassis dyno to measure the

dyno and vehicle losses, and then correct the chassis torque and HP to get

flywheel torque and HP?

How can I email Performance Trends a test from my DataMite software, for

Performance Trends to check out?

My Black Box II (or DataMite II) will not communicate to my

computer. What should I do?

What are the advantages

and disadvantages of an inertia dyno compared to a water brake?

Are there any general tips for

building an inertia dyno?

Could you elaborate on the advantages

(carb tuning related) of the A/F sensor over BSFC?

I have a

twin (2) roller chassis dyno. Do I put the RPM sensor on the front roller

or rear roller?

What is meant by Master DataMite Specs and

Master Dyno Specs?

Should the density altitude go up with the humidity?

I've tried to read up on it but cant make perfect sense of it. Can u please explain?

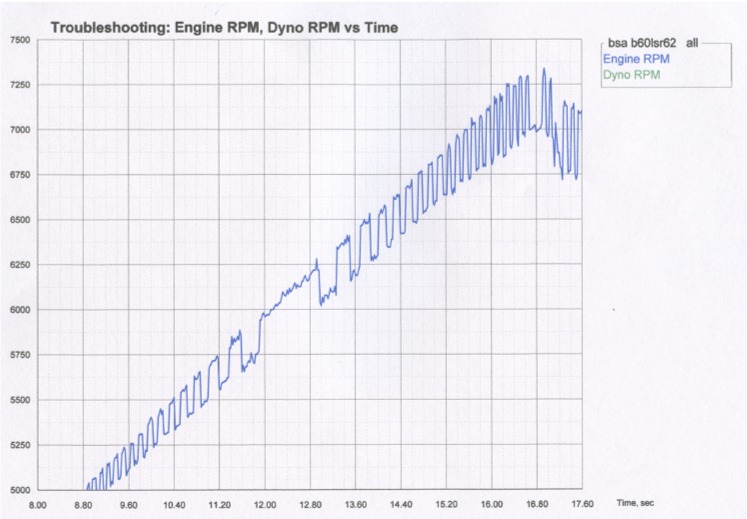

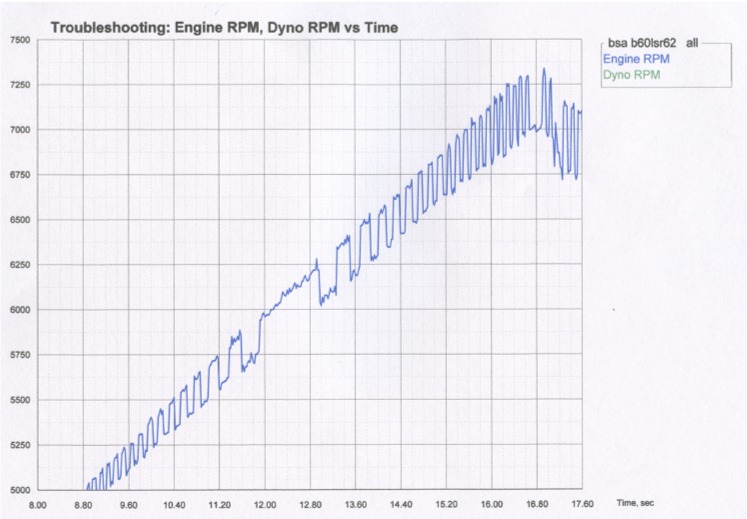

I'm getting erratic Engine RPM

readings. What can I do?

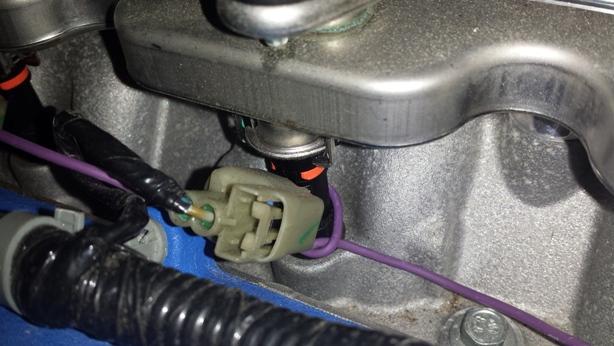

I am trying to get Engine RPM from

a coil-on-plug COP engine. What can I do?

My DataMite will hang up (stop updating the screen) during a dyno

test. What can I check?

How can I use the

weather readings in my Dyno DataMite software to tune carb jetting at the track?

I have a dyno run with

noise spikes in the RPM signal which the program can not edit out. What

can I do?

I need my brake dyno to measure

torque in both directions of rotation. Can you set up a load cell to do

that?

My dyno wheel (or

chassis roller) RPM measurements seem very jumpy. Why?

My Inductive

Pickup does not seem to read RPM. Why?

I'm using

the Engine Inertia correction for my water brake dyno. How can I see how

much effect it is having on the results?

The torque and HP

will peak at different RPMs depending on if I measure or calculate the engine

RPM on my chassis dyno. Why?

When running my dyno, the computer will sometimes lock up and I have to restart it. How

can I troubleshoot?

Why should I measure weather

conditions when engine testing? Does this produce what they call Corrected

Torque and Corrected HP?

My RPM Reading sometimes

reads double of what it should, and sometimes reads correct. Why?

How should I size a fan for my dyno room?

I have a fuel flow sensor from

a different data logger company, but am reading it with your DataMite. Why

doesn't it read until the flow is quite high?

How does a brake dyno

(water brake or eddy current brake) dyno work?

My torque and HP are low and both

peak at the same RPM. Why?

The air for my motor is different

than the air for the DataMite logger. Will the Weather Corrections still

be accurate?

Is there an

easy way to adjust the inertia of my inertia dyno to get the torque or HP number

I want?

You say your water brake controller

does not control the RPM sweep rate, but the valve opening rate. Why?

How

can I mount Performance Trends sensors on my Land and Sea (tm) Dyno?

Can I keep using

my SuperFlow (tm) controller if I use your DataMite for data logging and

analysis?

My peak HP (but could be

torque) seems to change a lot and is not repeatable. Why?

How can I check out my DataMite

System without a dyno or engine?

How do I get my DataMite program going on a new computer (transferred

over)?

How long are the cables for the typical Dyno DataMite system?

Are there instructions that come with the Dyno DataMite system?

My updated Dyno DataMite v4.2 A.062 gives an error message about

"data missing". What does this mean?

How can I make my flow meter

read Gallons per Minute for water?

My updated Dyno DataMite software is saying "x.xx seconds of data

missing" from my dyno test. What does this mean?

My A/F readings seem too lean,

especially at idle. What could be wrong?

How do I

measure ignition timing (spark advance) with my DataMite 4?

Drag Racing and Circle Track/Road Racing DataMite Data Logger Questions

My MSD Grid

(tm) ignition (or most any other high energy ignition) is producing electrical

noise and interfering with the RPM signals. What can I do?

My car seems down on power. How can I check it?

Can I measure spring

and/or shock loads on my car on the track?

I

click on the Run Number down the left side of the screen and it does not open

the correct run. What am I doing wrong?

Road Racing Software Questions

I want to optimize my car to

produce the quickest time to accelerate between 2 different MPHs. How can

I do this?

Can I

use my Data Logger data (from your DataMite or my own data logger) in your

Suspension Analyzer to see what my suspension is doing on the track?

Can the Circle Track/Road

Race DataMite analyze my shock's performance with graphs and histograms?

My RPM

measurements seem very jumpy. Why?

Shock Dyno Questions

Can you explain what the different Shock Dyno

Graphs mean?

My shocks are rated at

a 6 compression and 3 rebound. What does that mean?

Do you have any technical info

on reading the Shock Dyno results and adjusting the Shocks?

Can I measure spring

and/or shock loads on my car on the track?

I only have the

basic version of the software. What's the most accurate way to eliminate

the gas force from the data?

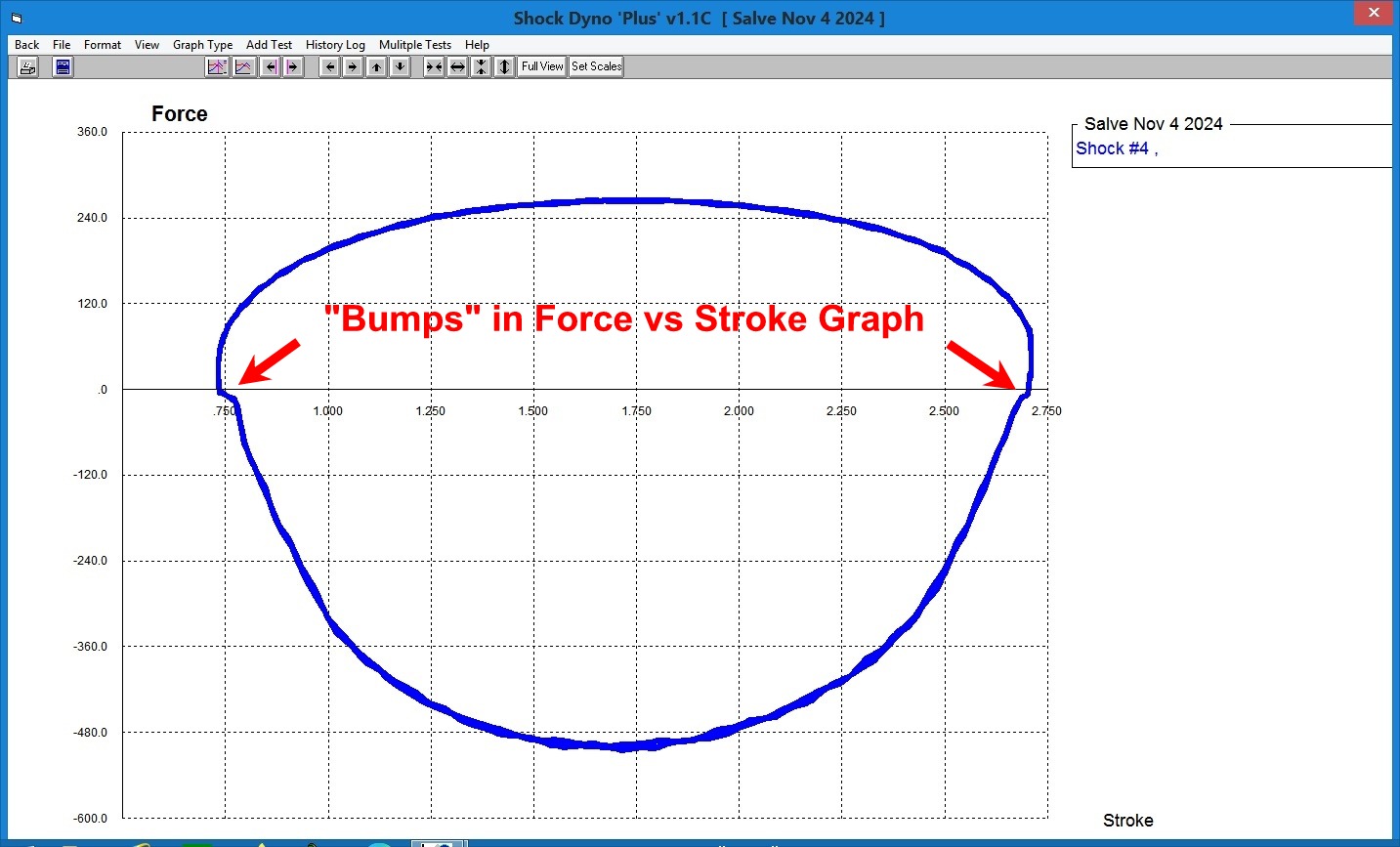

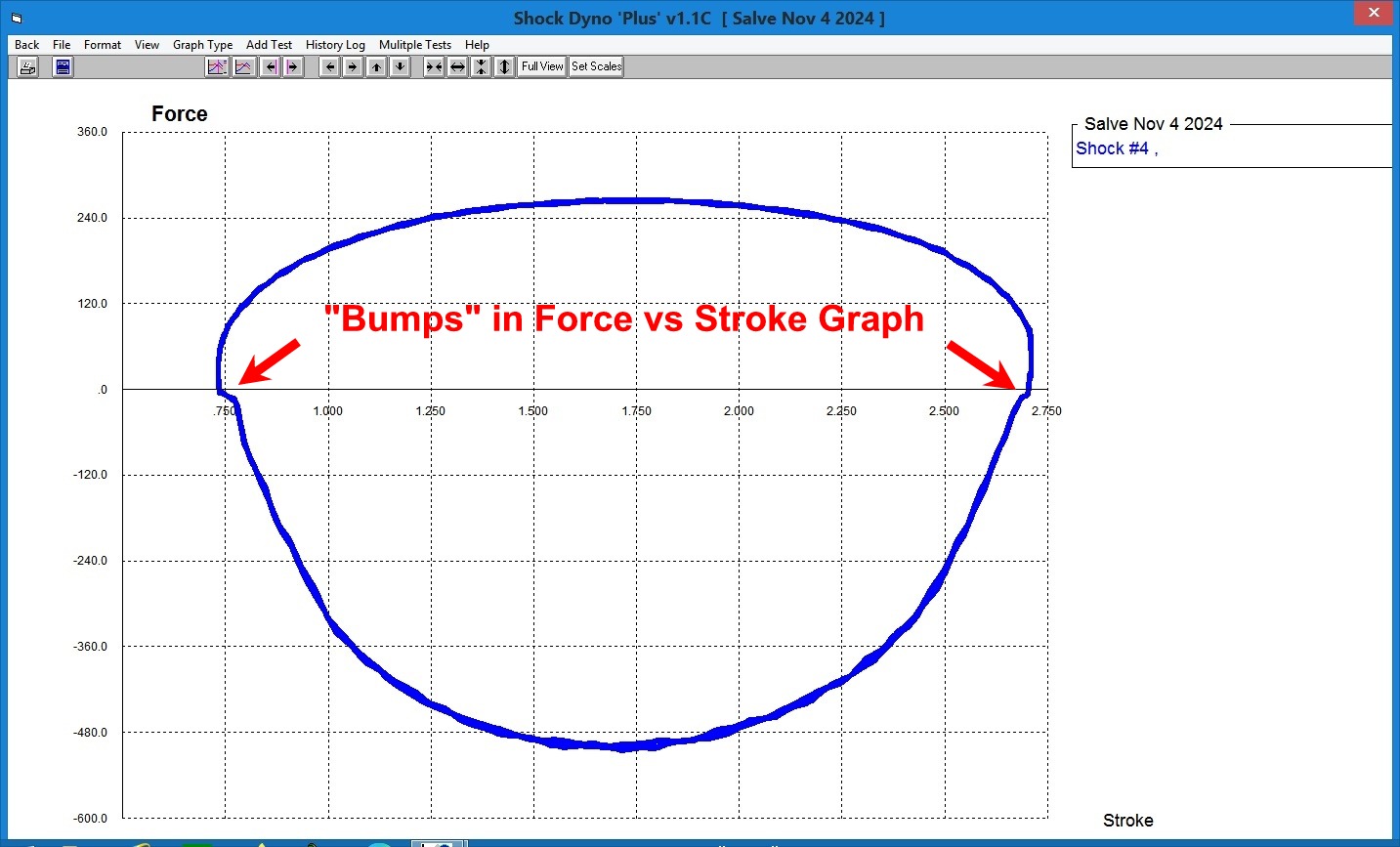

My "Football"

graph (sometimes called a "potato" graph) has "bumps" in

it. What does this mean?

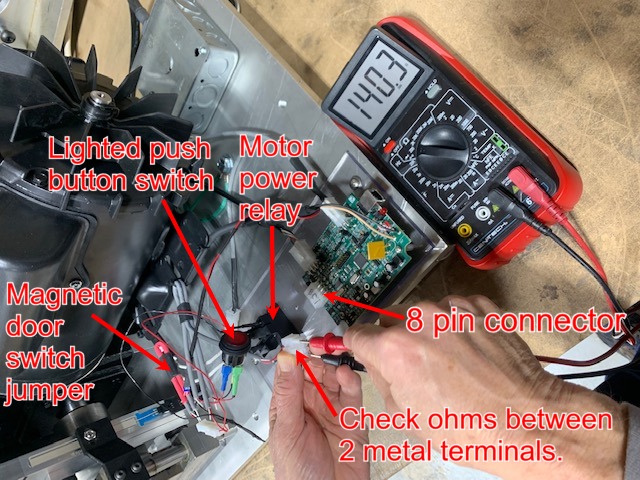

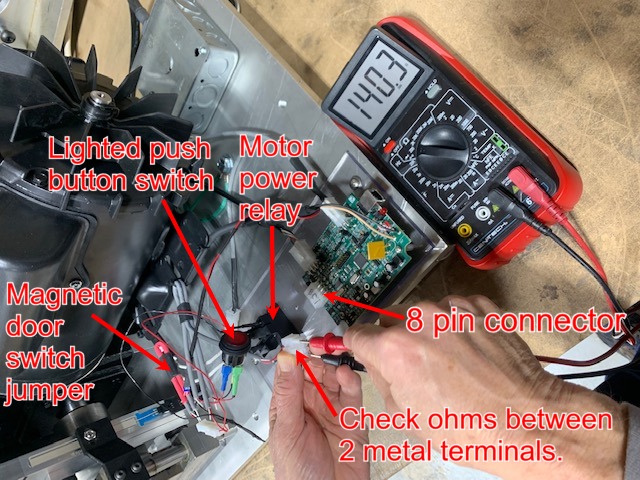

My dyno motor won't

start. How can I troubleshoot the wiring?

Questions on Other

Tools

How much blowby should my engine produce and

how much is "too much"?

My blowby measurement

changes from test to test. Why?

Can the Quick Cam

Checker create a cam file to be read by Engine Analyzer Pro or other Performance

Trends software?

Can the Quick Cam

Checker check a cam on the stand by barring over by

hand?

What is meant by

"aspect ratio" in the Spring Wiz program?

General Questions

Are Performance Trends' programs

compatible with Windows Vista and Windows 7, 8, 10 and 12?

Microsoft's newer operating systems, Windows Vista and Windows 7, 8, 10 and

11 have increased security, which

basically translates into more hassle getting programs installed and

running. Once a program is installed, you must run it as the administrator

or have administrator privileges. Most all of our current programs will automatically

force you to run the program as administrator, so it may be wise to update to

the latest version. When you double click on

the desktop icon, it will give you the option to "Cancel" running the

program or "Allow" the program to run. Therefore, other than

choosing the "Allow" option when starting the program, there is

nothing special you have to do when running our programs in Windows Vista or

Windows 7, 8, 10 and 11.

On rare occasions:

Occasionally you may encounter an error 339 or other "licensing

errors" when starting a program in Windows Vista or Windows 7, 8, 10 and

11. This

typically happens if the program was not run with administrator privileges.

To fix this situation:

- First, try restarting your computer a couple of times to see if the error

is fixed.

- Second, if the problem is still there and it says something like

"file not found" (not error 339), try installing again. This

time do a "Complete (typical) Installation" even if the installer

recommends just a "Refresh Installation". Important:

To eliminate other possible installation problems on Win 10, restart your

computer and then go to the installer. DO NOT run the program you are

trying to install before installing it again.

- Third (and this typically only applies to older programs which are not the

latest version, like EA32 when there is EA34 available), right click on the desktop icon and select

Properties. Then click on the Compatibility tab at the top of this new

screen, then check the box in the lower left for "Run as

Administrator". Then Click on OK. Now when you double click on

the desktop icon, it will should you the option to "Allow" the program to run.

If after doing this, you still have problems, shut down your computer and

restart it. Now try to run the program again and see if the problems have

been fixed. In most all cases, these steps will get the program running on

Vista and Windows 7, 8, 10 and 11.

If you are still have a compatibility problem with a current Performance Trends'

product and Vista or Windows 7, 8, 10 and 11, please email us at: feedback@performancetrends.com

We'll get on it as soon as we can, as all our products will have to be compatible with

Vista and Windows 7, 8, 10 and 11.

Back to Top

What if I don't know some spec the program is asking me?

Most all programs have a library of example specs loaded for you to start

with. For example, in the Engine Analyzer there are over 70 complete

engines pre-loaded by Performance Trends. Try to pick an engine close to

what you will be building. Then if you don't know some spec, just leave

the value which is already loaded for the example engine you started with.

Many programs have some way to "Get Examples" of components. For

example, in the Engine Analyzer, there are over 300 example Heads

pre-loaded. Some are specific like "Stock Chev Big Block Iron Rect

Port", and some are general like "Typical Ported 4 Valve for 3.8"

Bore".

Some specs are shown with a "Clc" button to their right which stands for "Calculate". An example is Compression Ratio.

You can enter a compression ratio directly by just typing it in if you know

it. Or you can calculate it from other specs like Chamber Volume, Gasket

Thickness, etc.

In most all programs, when you click on a spec a brief description of the spec

is displayed in the "Help" box on that screen. Many times this

"Help" includes a page number in the manual if you want more

explanation (for programs that come with manuals).

If you are building something completely different than any specs pre-loaded

in the program, make a good estimate of the spec and calculate

performance. Then make a change to the spec and recalculate performance

and see the effect on performance. Lets say you don't know the Frontal

Area for your 13 second, 66 Nova when running the Drag Racing Analyzer.

You see from the example vehicles that a 69 Mustang is rated at 22 square feet

and a 70 Corvette is rated at 19. You calculate performance for your 66

Nova using 22, and then 19 and see only a .018 second change in ET. This

tells you that for your particular car, Frontal Area is not that important, and

some number like 20 or 21 will work fine.

However, if you car was running in the 10s at 130 MPH or so, Frontal Area

would be much more important. Then you may want to come up with a better

way to estimate Frontal Area. Also see the "How do I

use a simulation program?" question below.

Back to Top

Why is the program predicting more performance than I'm

seeing on the dyno (or at the track)?

Simulation programs are predicting how things should work with all systems

working properly, carbs metering properly, ignition systems firing perfectly

every time, combustion chambers burning efficiently every firing, etc.

They can predict a mis-match of parts, but can not predict a improper operation

or failure of some component. Therefore, programs are usually predicting

"best case" performance.

Back to Top

How do I use a simulation program?

We are always getting phone calls saying that these programs must be

"magic" because the results exactly match the "real world"

of peak HP on the dyno, or ET at the drag strip. The important thing is not

that the program matches some dyno's measurements (because another dyno

can easily produce 5-10% different results), but do the programs match the

dyno's trends accurately.

For example, if you change header primary length 4 inches, does the program's

predicted trends match the dyno's trends. Even if 2 different dynos give

10% different HP numbers, both should show the same trends and both can be used

to improve engine performance. If the program can predict the trends

accurately, then the program can also be used to improve engine

performance. Fortunately, we get just as many phone calls saying the

programs are predicting the trends accurately also.

That's why we have more inputs in our programs than most others. Its

not to be more accurate at predicting performance, but to let you try more

modifications to see performance trends. What do I gain by

blocking the crossover? What happens if I can quicken my shifts?

What happens if headwind changes? Although the programs are very good at

predicting the final performance (like HP and ET), the true power lies in

letting you try nearly an unlimited amount of combinations to find the best one.

Back to Top

What is the advantage of using a simulation program?

Computers will never replace track or dyno testing. However, computer

simulations do have several advantages:

-

The difference between running 1st and last in

many competitive forms of racing may only be a 1-2% difference in HP, or

cornering ability, or reaction time. The way to become more

competitive is to make many small improvements (maybe only 1 or 2 HP at a

time) which add up to a larger improvement. In track or dyno testing,

test to test variability can "cloud" the actual results.

Computers repeat exactly each time so trends can be more easily found.

-

The computer is fast and cheap. Many

modifications can be done in minutes for free which would require weeks of

testing and thousands of dollars in parts (throw in a few bruised knuckles).

-

The computer is not limited by current

technology. You can try modifications

which your competition has never even dreamed of.

Try a "fast burn"

head which only needs 10° of spark at 8000 RPM.

Try headers or intake

manifolds with 100% anti-reversion.

Install a 4 valve head on a 5

HP Briggs & Stratton.

Try an extremely aggressive

cam with only 180° Duration and .800" valve lift.

Rev a low friction Chevy

(1" diameter

rod & crank journals) to 12000 RPM.

When you find a new design with big gains, you will

find or develop the required technology. Then use your dyno to verify and

fine tune the "computer optimized" designs.

-

Simulations let you get inside the engine or

vehicle to actually see and understand how things work. Watch Camber

change as the car rolls. Watch the exhaust blow down the exhaust pipe

when the exhaust valve opens.

Back to Top

How can I Email you a data file to show you a problem I'm

having with a program?

This example is for our Engine Analyzer v3.0, but is very similar for other

programs: The way to e-mail a file is to first save the engine file. Then go

into the ENGDAT folder and attached that file to an e-mail. Send the e-mail to: feedback@performancetrends.com

Be sure to include some explanation of why you are sending the file even if you

talked to use or Emailed before. We talk to and receive many Emails from

many people every day.

Back to Top

Can I use your Windows programs on my Apple Mac

(Macintosh) ?

Most modern Macs can run Windows programs without any problems. Apple

has its own software called Boot

Camp to run Windows programs. Third party programs like Parallels,

VMware

Fusion, and VirtualBox

are also available. Please check the specs of these programs, as they can

change. Most all Performance Trends programs are 32 bit Windows

applications.

We recently had a customer report he could NOT run our Circle Track Analyzer

v4.0 on Mac with 12 Core CPU, 30 Core GPU running Parallels Desktop 18, so there

can always be special cases.

for one customer's experience running our Shock Dyno program with his Mac Book

for one customer's experience running our Shock Dyno program with his Mac Book

Back to Top

What is error 429?

This error message can appear if a software company does not install the system files

correctly. If the error message includes the name of a file (commonly

Resize32.ocx), it probably means that there are multiple copies of this file on

your computer. The correct location for system files is typically in the Windows\System

or Windows\System32 folder. (Performance Trends always installs

system files to these locations to prevent this problem.) Copies of the

file in other locations are probably the problem.

For fix the problem:

- Click on Start (lower left corner of your desktop), then Search, then

Files and Folders.

- Then type in the name of the file causing the problem. In the

example above, you would type in "Resize32.ocx" (without the

quotes).

- For "Look In", be sure to select All Hard Drives.

- Then click on Search.

- You should at least find 1 occurrence of the file. If not, you did

not type in the name correctly or did not look in All Hard Drives. Try

again.

- If you find more than 1 copy of this file, rename those NOT found in

either the Windows\System or Windows\System32 folder as something

else. For example, rename Resize32.ocx as Resize32.ocx.bak (add .bak

to the end of its name). (Note: The folder where you find this

file should give you a clue as to what software company did not install the

system file correctly.)

- Now restart your computer and see if this error message is gone when you

run the Performance Trends program. If not, reinstall the Performance

Trends program and then see if the error message is gone.

Back to Top

My program runs very slow and is locking

up. The scroll bar in the table at the lower left is flickering.

We've seen this problem on our DataMite, Cam Analyzer and Port Flow Analyzer

programs. It could be a problem on other programs also but just shows up

differently. This is a rare problem and is NOT repeatable for any

particular computer, program or operating system, meaning we can not predict if

it will happen. The solution has been to reduce the screen resolution,

from say 1440 x 900 to something like 1024 x 768. This is done by clicking

on Start (lower left corner), then Control Panel (possibly Settings, then

Control Panel), then Display (possibly Personal Settings in Vista, then

Display), then Settings tab. Slide the slide bar for Resolution to a lower

setting and then keeping these changes.

Note: Since we wrote this FAQ, we have discovered what is causing this

problem, and have put fixes in most of our programs. If you experience

this problem, check to see if you have the latest version of the software at our

downloads page. If you don't have the latest,

update your software (there may be a charge depending on your version). If

you do have the latest, please let us know you are having the problem and we'll

get the fix implemented.

Back to Top

My security (virus checking) software says my program

is infected. What should I do?

First, it is very possible it is a "false positive", which means there really is NOT a virus

there. This is a common problem with the free virus checkers. Can you check with a different virus protection

software to see if it also says there is a virus there? If a 2nd program

does NOT find it, assume there is no virus.

If you think a program really is infected...

Install the same version from our website. This is not critical, but when asked, select to do a Refresh installation instead of a Complete (typical) installation.

See if the virus warning goes away.

If it does not:

- Is the warning saying the main ".exe" file is infected.

The reinstall described above should have fixed that. Therefore, it is

pointing even more strongly that it is a false positive. There really

is NOT a virus present.

- If the warning is coming from a small, support file (like a .doc or .txt

file), let your virus protection software deal with it (quarantine,

etc). If the virus protection software can not fix it, try

renaming the file by putting a .bkp at the end of the files name

(helpp12.txt changes to helpp12.txt.bkp). Then run the program and see

if it runs OK. If it does, delete the file. You may get an error

at some time when this file is needed in the future, but perhaps never will

depending on what you ask the program to do.

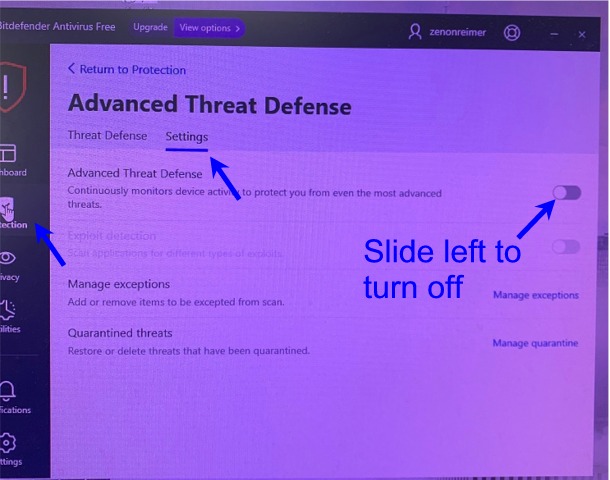

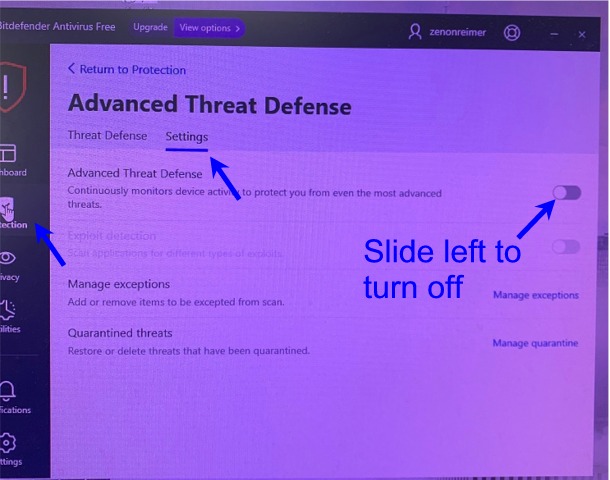

My software runs, but it

takes 1-2 minutes for the graphs to come up. What is wrong?

We have seen this when a customer is using Bitdefender (tm) security.

Everything works fine except the graphs take VERY long to come up, possibly up

to 2 minutes. If you go into the Bitdefenders settings screen, then click

on the Protection item on the left, it gives you an option of Advanced Threat

Defense (not shown in screen below). Click on the Advanced Threat Defense

option to see screen below, click on Settings and slide the Advanced Threat

Defense button to the left to turn it off. Close this screen and problem

should be fixed.

Back to Top

Performance Trends' software has

many messages. How can I get through these messages faster?

When I press the Function

keys in the Performance Trends software, nothing happens. Why?

These 2 questions are related, and we've produced a document to explain them.

for an explanation of these questions

for an explanation of these questions

Back to Top

Engine Software Questions

Are these (Engine Analyzer) Program's accurate?

(Background: This was asked on our website and we had several of our users

provide "glowing endorsements". Thanks everyone for the endorsements!)

Our registration cards run about 98% having positive to very positive

feedback. The 1-2% with negative feedback usually are because they bought a

program that was more than they wanted. Like Dave Koehler said, it may be best

to start with the standard Engine Analyzer unless you are VERY familiar

with computers and engines.

Any of our computer programs are tools, like a torque wrench or camber gauge.

They don't automatically make your car faster, but let you work smarter if you

use the tool correctly. You working smarter is what ultimately makes your car

faster.

No computer simulation replaces dyno or track testing. GM, Ford and Chrysler

have invested millions of dollars on simulation programs which can still be off

several %. That is why they still use dynos and test tracks. However, they are

still using (and increasingly so) simulation programs because it gets them

closer before they start building their first prototypes. It also helps them

understand what might happen with trade offs with the actual parts and what

potential problems they might encounter. For example, if the actual engine idles

at 18" vacuum, but the program predicted 20", the program can show

that reducing overlap 4 degrees gets them 2" more Idle Vacuum to get the

actual engine to idle with 20" vacuum.

(Update Feb, 2010) We should expand on this answer, as this is a very

common question. Probably once a month we have customer's call up and say

our Engine Analyzer program's are within 1-2% of the engine dyno. We love

to hear about this excellent correlation to a dyno, but realize that if they

took their engine to a different dyno, the second dyno's results could easily be

5% different from the first dyno. We also know that you could have your

first 4 engines you simulate match the dyno within a couple of percent through

the entire RPM range, and then the 5th engine could be 10% off.

What these Engine Simulation programs are doing is showing the potential

of a certain combination of engine specifications. They will help you

chose a cam, header, carb CFM rating, etc for a particular engine size and RPM

range, idle vacuum requirements, etc. They can not anticipate

problems, like a combustion chamber which does not want to burn

efficiently, an A/F mal-distribution problem, an oil windage problem in the oil

pan causing very high losses, etc.

For more explanation on Accuracy for these programs, open up our user manuals

and check the Appendix in each titled "Accuracy and

Assumptions". Click on the links below:

Std Engine Analyzer User's

Manual Engine

Analyzer Pro User's Manual

Back to Top

The Seat (advertised) Timing for my

cam does not match my cam's actual specs. How can I adjust this?

The Ramp Rating feature in Engine Analyzer Pro and Engine Analyzer Plus lets

you fine tune cam profiles. You can enter either .050" and seat

timing duration, OR .050" and .200" duration and calculate a Ramp

Rating to produce a cam profile which matches those 2 duration inputs. We

don't have a feature to match all 3 at this time (April 2012). However, in

Engine Analyzer Pro we do have an additional input to better define the cam

profile, the Designed Valve Lash. We let you say a cam is designed for,

say, .010" lash but specify that you will set the lash at .020".

This allows the program to "cut off" some of the more gentle part (low

lift part) of the opening and closing ramps.

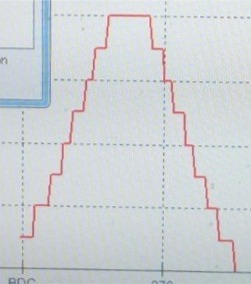

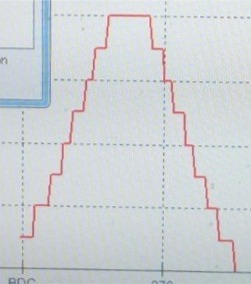

The graph below shows how we kept the Actual Valve Lash at .020" for 3

different Designed Valve Lash settings. You can see that the Duration at

Seat Timing (advertised duration) changed significantly, from the high of 320

degrees at .020" Designed Valve Lash down to 296 degrees at .005"

Designed Valve Lash.

Back to Top

The program's Seat

(advertised) Timing and Duration for my cam does not match my cam's actual

specs. Can the program still be accurate?

This is a common question, that Seat Timing events, especially the Intake

Closing event, is critical for predicting engine performance. One reason

for this is this number is used in the formula for Dynamic Compression Ratio

(compression calculated based on cylinder volume at intake closing instead of

total cylinder volume).

This would be somewhat true if the valve immediately snapped to full open at

the opening event and then snapped back close at the closing event.

However, that is not what happens. The valve is gradually opened and

closed to keep the valve train from self destructing. In addition, because

of a real valve train bending and flexing, the valve does not even lift when the

cam "tells" it to. You may have a cam which is suppose to close

at 84 deg after BDC, but once the engine starts running, the valve may actually

close at 80 deg, 76 deg, or even earlier. This is affected by RPM,

mass of valve train components, valve spring loads, valve train rigidity,

etc.

Look at the figure below. It shows how the actual valve lift profile is

significantly smaller than what you would think because of these factors.

The table shows that the intake closing event has dropped from 84 degrees (as

the cam is designed) down by 16 deg to 68 deg at 7000 RPM. It is not as

though these ramps are not important. They have a huge effect on how

quickly the valve opens once it does open, and on the stress put upon the valve

when it closes.

(click picture to enlarge)

(click picture to enlarge)

The picture below shows the detail of the closing ramp.

(click picture to enlarge)

(click picture to enlarge)

This table shows how the Intake Closing Event changes with RPM.

| Engine RPM |

Intake Closing Event |

| As cam is designed, with a perfectly stiff, zero- mass valve

train |

84 deg ABDC |

| 1000 |

80 deg ABDC |

| 3000 |

76 deg ABDC |

| 5000 |

72 deg ABDC |

| 7000 |

68 deg ABDC |

So, how do I use this information? Use the .050" (or 1 mm

(.040") lift for metric or .053 for Harley Davidson) specs for entering cam

data. For calculating a Ramp Rating (for Plus and Pro version), use the

.200" lift duration if you have it. Then if you want to further

refine the profile in the Engine Analyzer Pro, view the FAQ

above (click on blue link).

Back to Top

The Roots Supercharger I Installed

Shows No Boost. Why?

Roots superchargers make boost because they pump more air CFM than the engine normally would pump without a supercharger. If you install too small a supercharger or have too low a belt ratio, a roots supercharger will actually be a restriction and produce manifold VACUUM instead of boostÂ

You've chosen a supercharger which is TOO SMALL for this big an engine. Either put on a bigger supercharger or increase the belt ratio, either one will pump more air to the engine.

Click on the blue link to our Supercharger

Boost on line Calculator to better understand how this works.

Back to Top

I just made a

small change to the turbo specs and it made a HUGE difference in power.

Why?

A turbocharger makes power from the

engine's exhaust being force through the exhaust turbine. This turbine is

connected to a compressor on the inlet side to create boost pressure. If

this turbine is too big, then no pressure will be produced and no boost will be

produced on the inlet side. If you start to reduce the size of the exhaust

turbine, then pressure will be created, which will produce power to compress the

inlet air producing more boost. This more boost will produce more exhaust

flow which produces more boost. This affect will "snowball"

(feedback on itself) until very large levels of boost will be produced rather

quickly.

This is why a small change in some engine specification, RPM, Turbocharger

Specs, and especially Exhaust Turbine Nozzle Diameter can have a HUGE

effect on the performance. The graph below shows a Porsche 2.5L with a

Turbine Nozzle Diameter at 1.7" diameter (too big) and the factory size of

1.3" (sized correctly). Just this relatively small change bumped up

the boost from about 2 psi boost up to about 20 psi, and the power almost

doubled from less than 200 to close to 400 HP.

In the Engine Analyzer programs, what is the advantages

and disadvantages of going higher than 75% on the Total Exh/Int %?

The 75% number has been developed from experience over the last 60 years or

so. Taylor from MIT developing aircraft engines in WWII was one the first to

come up with this # that I know of.

If you have more than 75%, it does NOT means you should restrict the exhaust.

It does mean that there is probably more benefit to enlarging the intake valve

at the expense of the exhaust valve. Since a bore only allows an intake and

exhaust valve combo so big, there usually must be a tradeoff. If you make the

intake bigger, the exhaust must get smaller.

This 75% (85% for Nitrous Oxide or supercharged) is VERY general, and

reported for info only. It is not used in the program to predict performance, as

those calculations are much more detailed.

How do I simulate a restrictor on an EFI engine with a

plenum and individual runner throttle plates?

The best way is to pretend the vehicle is using a single plenum EFI Type

manifold with appropriate length runners, a plenum matching your air box, and

then a restrictor ahead of that To calculate the Carb/Throttle Body CFM rating,

click on the Clc button for Carb/Throttle Body CFM Rating. Then just use the

dimensions of the restrictor. (The restriction of the other throttle plates in

the runners is negligible compared to the restrictor.) For a "perfectly

designed" venturi type of restrictor, the "% Improved" spec in

the Clc menu should be about 150%.

Why does the spark advance value only increase by maybe

10 degs from idle to 3000 (even on stock setups) when actual distributors have

15-24 degs of advance?

Required spark advance is a complicated subject, especially when you the

program tries to predict when detonation will occur. A/F distribution, thermal gradients

(differences) across the heads, pistons, etc, combustion chamber design, are

just a couple of things the program must make assumptions about. Then we have

the factory, which has many different things to consider than just detonation

and best power, things like: lighting off the catalysts fast, max catalyst

temperatures, transient response, knock sensor calibration, cold start

strategies, warranty, transmission durability, etc, etc. That the program does

not match the factory calibration is not surprising.

Just a note, idle at 700 RPM is a very different condition than full throttle

at 700 RPM, both requiring very different spark advance. Idle or some part

throttle conditions may want up to 50 degrees of spark advance. Because of the

light load and possibly EGR it may not detonate. But the same RPM at full

throttle may only be able to run 10 degrees before it starts to detonate.

Which cylinder heads have a "Compact Wedge"

combustion chamber?

Compact Wedge is a chamber which has had considerable race development to

improve Burn Rate and efficiency (power for a given amount of fuel & air

intake). This includes "cutting edge" Winston Cup, Formula 1, and NHRA

Pro Stock type of engines. The "chamber" is actually a combination of

the chamber in the head and the Piston Dome design, and how closely they come

together in the quench zone.

Most any combination that simply takes "this head" and puts it with

"that piston", without careful dyno study, would NOT be considered a

"compact wedge".

How much harder is Engine Analyzer Pro compared to Engine

Analyzer?

When people ask your question, we usually recommend the std Engine Analyzer

which sells at a much lower cost. Should you get comfortable with it and want to go to the Pro

version later, you qualify for a significant discount. Therefore, you are only out

small amount

for getting the standard Engine Analyzer first.

The Pro's more inputs and many more features (menus, commands, etc) can be

overwhelming at first. More inputs can also mean more chances to input a wrong

measurement, which will produce more inaccurate results than accurate results.

Why can't I get the Engine Analyzer to match the

factory torque and HP ratings for 1960s muscle cars?

Unless you have the actual curves and know how the engine was set up, it is

difficult to know exactly what the factory was doing. In the "old

days", the factory would put on headers, block the crossover, change the

spark and fuel curves, run open exhaust, etc, etc to get "factory

ratings". This changed around 1972 when power ratings suddenly dropped.

You've seen the "heads up" comparisons between old and new production

cars in recent magazines. How else is it possible for modern 300HP Corvette to

"blow the doors off" a 1968 425HP Corvette.

Also, if the factory marketing department wanted to "push" low RPM

torque, they would simply pick a low RPM point off the torque curve, even if it

was not the peak. In addition, dual plane intake manifold tuning is difficult to

simulate accurately. Some of these engines could have made more low end torque

than the Engine Analyzer program estimates.

Back to Top

How do I enter or calculate the "Corrected

Compression Ratio" for my supercharged engine?

The Compression Ratio stays the same, whether supercharged or not.

Compression Ratio is a volume ratio and does not change with pressure. To try to

explain that supercharging increases cylinder pressures and the tendency to

knock (detonate or ping), people have come up with this idea of an

"effective" or "corrected" compression ratio based on boost

pressure and static compression ratio. However, if everything that effected

cylinder pressures and the tendency to knock would have an "effective

compression ratio", then we would have one for cam timing, carb size, port

restrictions, type of fuel, nitrous oxide, RPM, etc., etc. This term is rather

"old fashioned".

The Engine Analyzer program is considering all these aspects of supercharging

"behind the scenes". You will notice that torque (an indication of

peak cylinder pressures) goes up and the tendency to spark knock goes up when

you start increasing boost. (The Pro version would actually graph you cylinder

pressures with and without boost for comparison.)

At present, we don't feel a need to display a "Corrected Compression

Ratio" in the Engine Analyzer Results. That is not to say we won't do it in

a future version if we get other requests.

Back to Top

Is the Engine Analyzer doing ECA (Engine Cycle Analysis)?

In general, ECA means to analyze the Cylinder Pressure over the 720 deg, 4

stroke cycle. Usually this is by measuring cylinder pressure and crank degree

very precisely and quickly. Much can be learned about performance by doing this.

EA30 does NOT display this type of simulated data, however the EA Pro does. EA

Pro also displays many other "cycle" details like port pressures and

velocities, piston acceleration or thrust on the cyl. wall, pushrod force, valve

opening, etc. If this is the type of detail you want, I'd recommend the EA Pro.

Download the demo to see yourself. If you already own EA30, you get a discount

upgrading to EA Pro.

Back to Top

Why does the Engine Analyzer Pro show that some Thermal

Barrier Coatings reduce performance?

Coatings which reduce friction should always help performance. Coatings which

reduce temps on the intake port/runner should always help performance by keeping

the intake charge cool and dense. However, coatings which reduce thermal

transfer to the piston or cylinder head do 2 things:

1) They reduce heat transfer (loss) which should help performance.

2) They usually increase the surface temp of the piston which should hurt

performance.

The total effect of both things determines if there is a net gain or loss.

Engine Analyzer Pro v2.1 "C" or later has an alternate coating choice

which reduces heat loss but doesn't increase the surface temp as much. Coating manufacturers.

say this is more typical of "modern coatings". Unfortunately, we don't

know which description of "modern" or "typical" is more

accurate.

Back to Top

Does the Engine Analyzer or Engine Analyzer Pro consider

Port Size (volume) when estimating Performance?

Yes, the Engine Analyzer Pro (and even the standard and Plus Engine Analyzer

programs) will show the effects of

large ports at high and low RPM. Both programs ask for port volume (or average

port diameter) for both the head and the intake manifold runner. Most other

programs don't ask for these details, but they are required for reasonably

accurate predictions. You will definitely see low RPM performance suffer when

ports get too big.

IMPORTANT: You can enter a very small or large port size, and the flow

settings for the port will not change, as they are a separate input. For

example, you can specify a 0.5" Average Port Diameter that flows 500 CFM,

which is impossible. SO, it is important that if you change port volume to also change port flow numbers to match this change.

How much the flow will change when you change port volume can typically only be determined on a flow bench.

Back to Top

My Turbo catalog only lists lb/min for airflow not cfm

as Engine Analyzer uses. Is there a formula to convert lb/min to cfm??

Multiply lb/min by 13 for an approximate CFM.

Back to Top

Can the Engine Analyzer and Engine Analyzer Pro be used

for small engines, like a 5 HP Briggs?

Yes, we have checked both programs against dyno runs from 5 HP Briggs

engines, and other small 4 stroke engines. The agreement is quite good, but we

haven't checked it as much as we have with typical V-8 dyno runs. Its just

that we've got a lot more V-8 dyno experience.

When HP and torque numbers are reported at very low numbers, they are

reported to the nearest .01 ft lbs and HP. Inputs like Bore and Stroke can be

specified to .001 ". The displacement is calculated with no rounding for

performance calculations. When displacement is displayed, it is rounded to the

nearest 0.1 CC.

Back to Top

The Spark Curve reported by the Standard Engine Analyzer

starts high, then drops down, then increases again. Is this possible?

The standard Engine Analyzer tries to make the spark curve somewhat

automatic. It gives the engine as much spark as the program thinks the engine

wants, but not so much as to let the engine detonate (spark knock) for the given

conditions (intake air temp, humidity, fuel octane, CR, etc.) The EA Pro is not

so automatic, but does give you much more freedom to try different things with

spark advance.

In the actual engine, spark advance curves have been developed from what a

simple centrifugal advance could do in an "old fashioned" distributor:

start at the "initial advance", then at some RPM start advancing to a

higher "full advance". This approximately follows what most engines

"want".

Most spark requirements increase gradually with RPM. However, if your engine

has a big cam, for example, it may produce poor low RPM torque (poor combustion

due to poor mixture) and may benefit from more advance until the engine gets

"up on tune", where spare requirements then fall, then pick up

gradually as RPM increases. Most of the time you really aren't interested in max

performance until the engine does get "up on tune", anyway, so don't

be too worried about spark advance at low RPM. Just be sure not to let the

engine detonate.

Another possibility is if the engine is Supercharged or Turbocharged, at low

RPM there is little boost so the engine can run a normal amount of spark. Then,

when boost starts to come on, the program "pulls out" spark advance to

avoid detonation. Then as RPM increase, spark can be put back in as detonation

is not as likely at higher RPM.

Please note that retarding the spark advance a few degrees from optimum

timing will not show a large loss in performance, but will give you a better

safety margin for avoiding detonation.

Back to Top

Do the Engine Analyzer's consider Turbo A/R in their

calculations? Do I alter the Turbo CFM rating to simulate different exhaust

turbine sizes?

Our Engine Analyzer v3.0 and Pro v2.1 both have specs that describe the

turbine (exh) side of the turbo separately from the compressor side. A flow map

describes the compressor, not the turbine at all. Turbo A/R does NOT affect the

flow map, but the turbine size, and how quickly (at what RPM) the turbo starts

to develop boost.

Back to Top

I have cam timing specs .020" lift intake and

.025" lift exhaust. Currently I am using the valve lift graphs to

determine where the .050" lift point is from where I see the .020" and

.025" lifts. Is there an easier way to figure this out?

I assume you mean that you have timing specs when the Valve Lash of .020 to .025

has been taken up and the valve just starts to open. That is what the program

calls seat timing. Just specify seat timing as the method of

rating events. However, seat timing is not nearly as accurate as

timing at .050", as explained below.

What you want is to have the program simulate the most important and largest

amount of the cam profile accurately. That would be duration at .050",

.100", .200" etc., the higher lifts. If you use .050" for rating

the cam events, this is done much more accurately, because the gradual part of

the ramps is over. You are already at the higher lifts.

Cam lift changes very gradually at the very beginning or end of the cam lobe

where seat timing is measured. For example duration at .001" could be

320 degrees. Duration at .002" for a cam with mild ramps could be 305

degrees, but for a cam with aggressive lobes could be 316 degrees. This allows

minor differences in cam lift aggressiveness to produce very different timing

figures.

Using the same seat timing events for 2 cams,

minor differences in design can produce totally different durations at

.050", .100", .200", etc. That is why the cam grinders adopted

the .050" cam lift point for comparing cams. It is much more accurate than

seat timing.

Also, remember, the Engine Analyzer graphs shows valve lift:

valve lift = tappet lift x Rocker Ratio - Valve Lash

or

tappet lift = valve lift / rocker

ratio + lash

Assuming .020" lash and a 1:1 rocker ratio, if you look for .025 lift on

the graph, you are getting cam or tappet lift at .025" + .020 , which would

be .045 inches cam lift. With a rocker ratio of 1.5, this would be a cam lift of

.025 / 1.5 + .020 = .037 cam lift.

Back to Top

How do I enter the weight of my crankshaft, pistons or

rods so I can see the effect on HP?

These weights do affect the rotating inertia of the engine. Rotating

inertia is an input in the Short Block specs screen, however currently there is

no way in the program to estimate the change in rotating inertia for rod or

piston weight changes. This is addressed in our Rotating

Inertia Calculator program, and may be included in Engine Analyzer Pro

updates.

Rotating inertia only affects power when the engine is accelerating, like in

a vehicle when it is accelerating or on a dyno's accelerating

("sweep") testing, say at 300 RPM/sec. Then some of the engine's

power must be used (lost) to accelerating the engine's own internal

inertia. The lower the inertia, then the less power lost.

People often think that because a piston is lighter, it takes less of the

engine's power to accelerate it down from TDC. That is true, but what they

forget is that energy is recovered when the piston is decelerated when it again

approaches TDC. Therefore there is no net loss when running steady state

dyno tests. (Note that there could always be some secondary effects on

performance that are very difficult to model. These could be things like

lighter pistons don't stretch the rod as much, therefore things like compression

ratio or ring seal is maintained, or lighter pistons "rock" in the

bore differently as they approach and accelerate from TDC, thus sealing or

friction could be slightly different, etc.)

Then you may ask "Why do engine builders strive to use lighter pistons

and rods?" That's because lighter pistons and rods put lower stresses

on the rods and rod bolts. Lower stresses mean longer durability and/or

you can rev the engine higher. With proper choice of cam, Head Flow, etc.,

most anything that lets rev the engine higher will produce more HP.

Back to Top

What is the formula for determining Intake Valve

Closing angle in the Compression Ratio Calculator?

The "Formula" is quite complex (many formulas actually) and has

to do with our Cam Profile Designer routines. At .050 tappet lift, the

valve may still be .100 " off the seat (not closed). For Dynamic

Compression ratio you want to know when the valve is ON the seat so pressure

will start to build in the chamber, which changes with profile type, Hyd vs

Solid Lifters, Lash, etc. for a particular intake closing at .050" tappet

lift. If you know the intake closing at .000 valve lift (seated timing),

you should enter it directly. (The .006" lash point is used for

hydraulic lifters because they are assumed to have about .006" effective

lash.)

Back to Top

Why does the Engine Analyzer and the Engine

Analyzer Pro give different results for detonation (spark knock)?

The 2 programs work differently:

EA30 retards spark to not allow detonation to occur. EA30 does not report

detonation level, just spark advance.

EA Pro runs the spark curve you give it or one it believes will produce best

power and just reports the detonation level.

Behind the scenes, the 2 program's calculations are quite different, especially

how they determine detonation levels. As we say for both, you can not use

the absolute levels of detonation (or spark curve in EA30) to tune your engine,

just use them to see trends. This cam or CR will produce about this much

more or less detonation.

Back to Top

Why is there a dip in the torque and HP curve at 3500

RPM?

All highly tuned engines with high overlap cams will encounter good and bad

tuning peaks through their RPM range. See Appendix 3 in user's manual

"Intake and Exhaust Tuning". For header primaries from 30-40

inches long, a "bad peak" for exhaust tuning comes around 3000-5000

RPM, where you will see a "dip" in the power curves. This is NOT

an indication of bad performance, just a "necessary evil" to get good

tuning and performance at other RPMs. If you try to eliminate this dip

(close up overlap), you will hurt performance at other RPMs. You can move

where this dip occurs by changing header primary length. For example,

going to longer primaries will move the dip to lower RPMs.

Back to Top

How do I build

an engine to run a certain quarter mile ET and MPH?

You would need both an Engine Analyzer (std, Plus or Pro) and Drag Race Analyzer

(std or Pro). The Engine Analyzer builds the engine and shows the torque and HP curves. The

Drag Race Analyzer takes the power curves and couples it with vehicle specs to come up with ET, MPH, etc. You can

Auto-link the 2 programs so that each time you make an engine mod in the Engine Analyzer, the ET and MPH (and 60 ft, finish RPM, etc) from the

Drag Race Analyzer are also displayed in the Engine Analyzer results.

Back to Top

How can I speed up the

Calculations in Engine Analyzer Pro?

The Engine Analyzer Pro's calculations are VERY detailed and do require a

significant amount of time to perform accurately. Some things which will

speed up the calculations include:

- Use a fast processor computer. Note: At this time we can not

take advantage of Dual Core Processor computers.

- Run as few RPMs as possible. This means using large RPM increments

(500 RPM or larger). Also, start at a high RPM. Low RPMs are

VERY time consuming, especially if the engine is unstable at those RPMs

(high overlap cams).

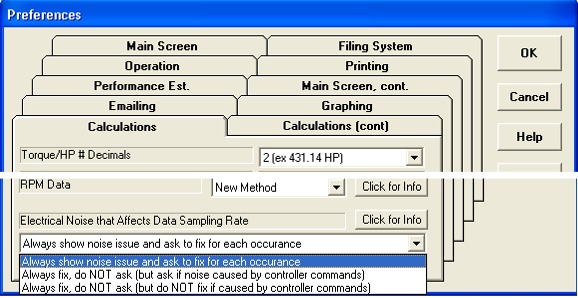

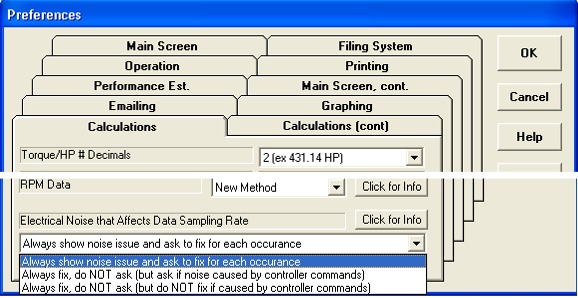

- Click on Preferences, then Calculations tab. Set the Calculation

Repeatability to "Standard".

- Use "Simplified Collector" in the Exhaust Specs as the

"Detailed Collector" takes more time.

- Turn off Valve Train Dynamics in the Cam/Valve Train Specs screen.

- Use the "Chain Calculation" feature to run through several

calculations unattended (like overnight). Then investigate the best 5

or 10 combinations for further refinement.

Once you find some promising combinations, you can go back to smaller RPM

increments, turning ON valve train dynamics, etc. and do more refinement.

Back to Top

I've run the same

exact conditions and the Engine Analyzer Pro does not give the exact same

results. Why?

The first thing you must understand is there is NO exact

answer. Each torque, HP, spark advance, etc result at each RPM is an

approximation. The calculation method for complex systems like an engine

is an iterative approach to problem solving, and it is the only way it can be done.

This involves assuming certain conditions going in, see what the answer is and if the results confirm your assumptions were

close enough. See Appendix 2 in the Engine Analyzer Pro user's

manual for more explanation.

If you watch the Tuning Pressures graphs during the calculations, you see each cycle's pressure waves. These waves are

NOT exactly the same from cycle to cycle for the same RPM and

conditions. The program must decide when to stop the calculations after the cycles appear to repeat

"good enough", within a tolerance, maybe within 0.5%. This tolerance can

NOT be zero difference for an exactly repeatable answer, or you will

NEVER get an answer.

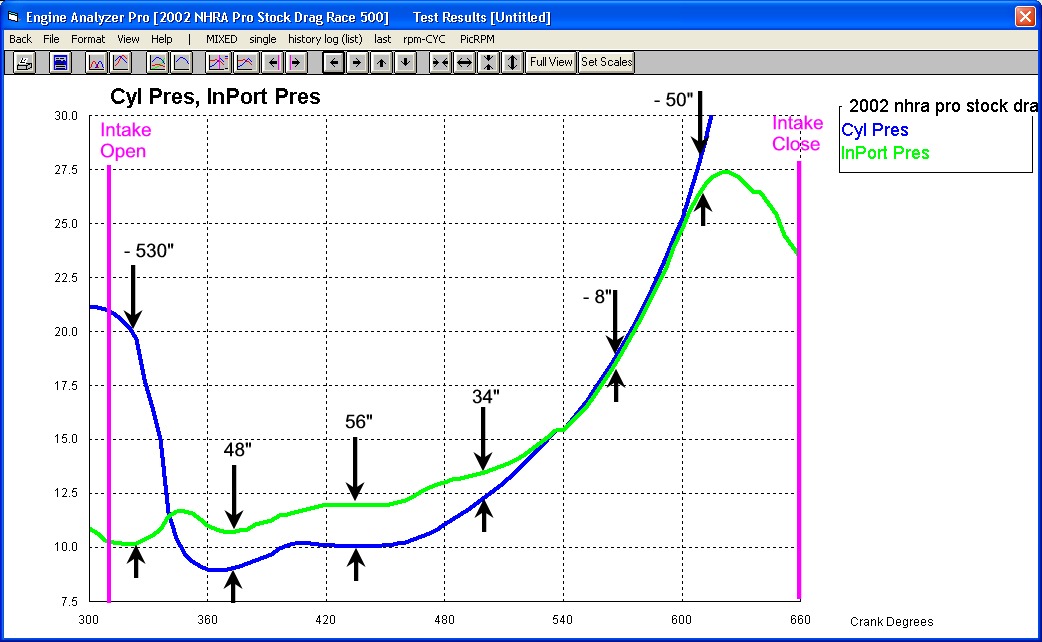

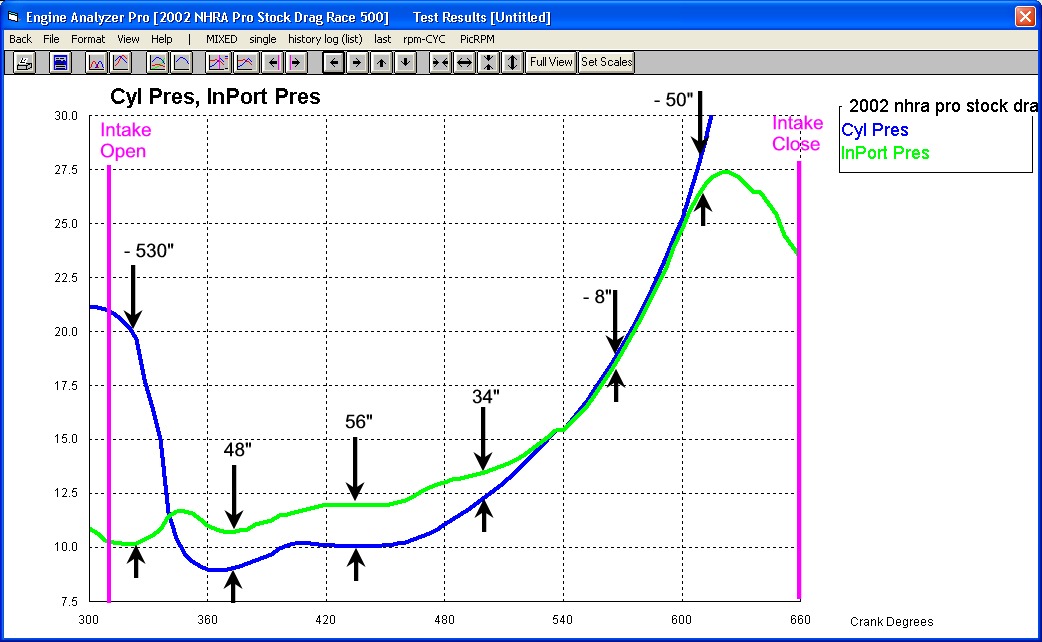

The graph below shows the Intake Port Pressure waves for the exact same

engine at 8000 RPM. If the pressures were EXACTLY the same, you would only

see the green line. Because they are slightly different, you can see the

blue line also underneath the green line. The test with the blue line

showed 908 HP at 8000, the green line showed 910 HP. (Remember that there

is more affecting these results than just Intake Port Pressure. Exhaust

Port Pressure, burn rate, heat transfer, etc all have an effect on the end

result of 908 vs 910 HP.) However, in both cases, the

"tolerance" for an acceptable answer was met. The difference of

2 HP our of 910 HP is only 0.2%.

You should also understand that each cycle (cylinder firing) in the real

engine is not exactly the same as the last. Cycle to cycle variation of

IMEP (torque on top of the piston), can easily be 5.0 % or more. If you

just took, say 3 cylinder firings to get the torque at each RPM, you would get

VERY non-repeatable dyno runs. But because good dyno software averages out

hundreds of firings together, you can get repeatability of 1.0 % or better,

which is still not nearly as repeatable as the Engine Analyzer Pro.

Even our smaller Engine Analyzer programs use this iterative approach.

However, their calculations are not nearly as complex so you do get almost

exactly the same answer for each particular engine condition.

Notes on Repeatability:

Engine's which are less repeatable are those with high overlap cams, high

specific output (high HP/cubic inch) and turbochargers.

To improve repeatability, increase the "Calculation Repeatability"

under the "Calculations" tab in the Preferences section. This

will make the calculations take more time, but will improve repeatability.

Back to Top

What should I adjust to get the

Engine Analyzer results (std, Plus or Pro) to match my real dyno results?

The Users Manuals for both the standard, Plus and Pro versions talk about

this in Appendix 4 in each. Click on the blue links below for either

manual:

Do not adjust some input spec which you know for sure. For example,

you may find that reducing the head flow 20% will make the program match the

dyno results. But now the program will show a bigger improvement in

performance from a bigger cam than the real engine would show on a dyno.

That's because the program sees the heads as being more restrictive, and a bigger cam

improves the overall flow significantly. The real difference could be that the dyno

calibration is low or high, the dyno has a different amount of accessories it's

driving on the front end, etc.

You should enter all the numbers you know for sure, accurately. Then

just accept the difference in the results. This way the program can better

predict the change

in performance from an engine change (modification). Remember, dynos vary in the

results they report, especially chassis dynos which can be 15-25% lower than an

engine dyno. The Engine Analyzer Pro lets you enter a chassis dyno

correction factor to reduce the output to match a particular dyno. Also,

the Engine Analyzer programs predict the results you would expect to see on an

engine dyno doing a step test, unless you have specified otherwise in the Engine

Analyzer Pro.

Back to Top

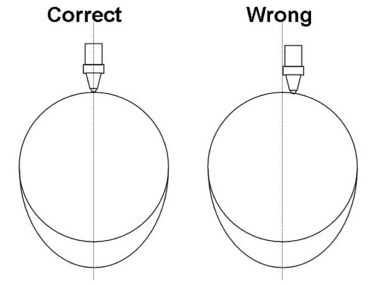

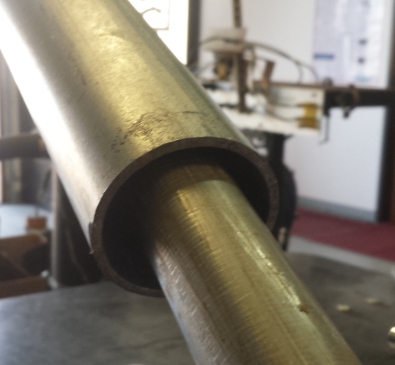

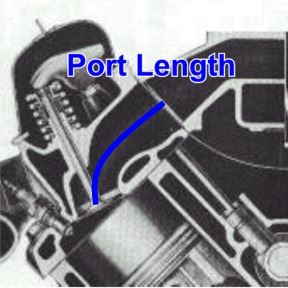

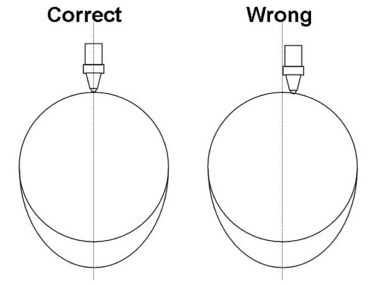

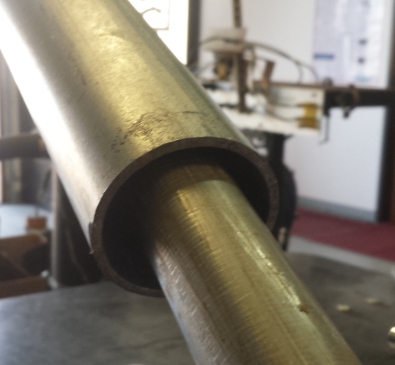

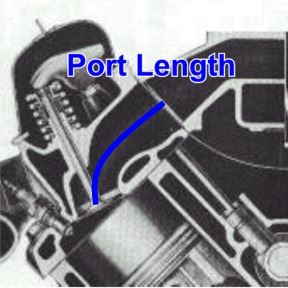

I'm a little confused about

measuring Port Length. Is it measured along the short side of the port?

Port length is measured from the center of the port at the mating surface to

the manifold (or header on the exhaust side) down the middle of the port to the

valve. This picture may explain it best.

Back to Top

How can I export the

cam profiles and cylinder flows and pressures from Engine Analyzer Pro to Excel?

The Engine Analyzer Pro produces what we call RPM Data like

torque, HP, fuel flow, BSFC, etc at each RPM of the run. It also produces Cycle

Data which are things like cylinder temperature, cylinder pressure,

piston thrust on the wall, intake valve lift, intake valve flow, etc at every 4

degrees of crankshaft rotation. (Behind the scenes the data is being

calculated at something more like every .1 degrees, but we only report it

at every 4 degrees.)

This Cycle Data is one thing which really sets the Engine Analyzer Pro apart

from other simulation programs. You can graph it and gain tremendous

insight into the internal workings of your engine. However some people

want to export it into other programs like Excel (tm) to do their own

analysis. The Engine Analyzer Pro provides several methods to let you

analyze and export this Cycle Data.

Shown below are some tips for producing Cycle Data graphs. Choose Cycle

Data graphs by clicking on the "rpm-CYC" menu option. If you are

currently doing RPM data, this menu option is shown as "RPM-cyc".

Then you have the choice of doing Cycle Data graphs of "MIXED" data

(from one to 4 different cycle data types on one graph like in the graph below

of Int and Exh Valve Lift) or just "SINGLE" data graphs (where you

pick just one data type from a list as shown below).

(click image to enlarge it)

(click image to enlarge it)

You can also use the "See-Engine" option at the top of the tabular

results. Click on "See-Engine" to bring up the Piston-to-Valve

Clearance screen. There you can watch the interaction of the valve lifts,

Piston Position, cylinder and port pressures and flows to truly better

understand what goes on inside the engine. There you can also click on

Options to bring up the See-Engine Options screen, where you can choose to

export Tabular Data of the data used on this screen to Notepad.

(click image to enlarge it)

(click image to enlarge it)

You can also use the "ASCII File" option at the top of the tabular

results. Click on "ASCII File" to bring up the Export ASCII File

screen. There you can chose most any RPM Data or Cycle Data to export to

an ASCII (text) file in various formats. This file can be imported to

Excel for most any analysis you wish.

(click image to enlarge it)

(click image to enlarge it)

Back to Top

How can I create a cam file to be read by

Engine Analyzer Pro or other Performance Trends software?

The Engine Analyzer Pro and many of our other engine programs can read a

detailed cam file, which typically contains a tappet lift for every cam degree

(every 2 crank degrees). These formats include Cam Dr (.c1), Cam Pro Plus

(.cpp), S96, Andrews, Comp Cams, to name a few. When you want to create a

cam file from generic data, like possibly Excel spread sheet data, you need to

create one of these files. Missing just one line of data, or missing a

comment line is enough to throw everything off. Therefore we will try to

explain the best course of action to produce a cam file.

First, the Comp Cams and S96 formats are the easiest to produce

from Excel or other text data.

Comp Cams format consists of 42 lines of comments followed by 360

tappet lift data points.  for an example file.

for an example file.

S96 format consists of 360 tappet lift data points followed by an

additional 36 lift points. These last 36 points are typically the same as

the first 36 points, but are used by some software to confirm the reliability of

the measurement. If these last 36 do not match the first 36 very well,

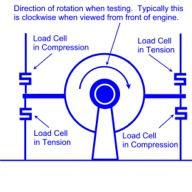

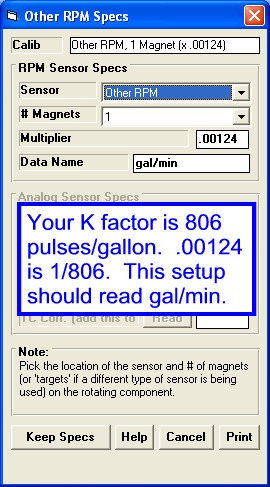

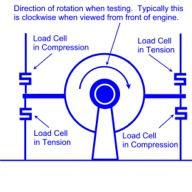

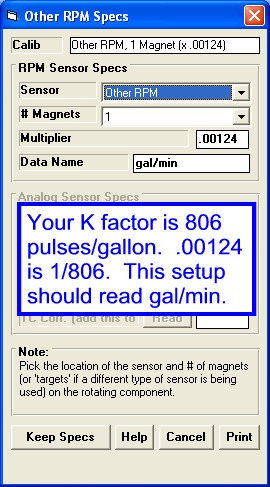

something is wrong with the measurements.  for an example file.